Guidelines for Selecting Vacuum Furnaces

Vacuum Furnaces For Creation of New Values

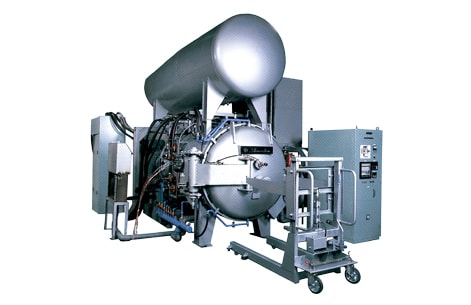

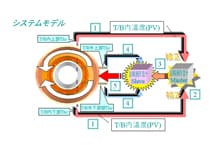

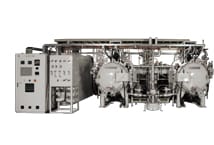

Some remarkable new materials have been developed and manufactured in recent years, for which the heat treatment process has gained considerable attention, specifically the high added-value and reliability offered by vacuum furnaces. The leading manufacturer of vacuum furnaces, Shimadzu Mectem utilizes experience gained from delivering over 1000 vacuum furnace systems to provide a variety of models suited for a wide range of applications.

Example of Precision Superhard Parts Treated in a Vacuum Heat Treatment Furnace

Example of Treatment Using MIM Dewaxing Sintering Furnace (clock parts)

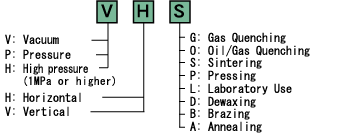

How to Read Series Name

Guide for selection of vacuum furnace

| Sintering |

Brazing |

Quenching |

Max. Temp |

Pressure |

|||

|---|---|---|---|---|---|---|---|

|

MIM |

fine ceramics |

Cemented carbide alloy |

|||||

| HHS | ○ | ○ | 1600℃ | 10-1Pa~6MPa・G/10 MPa・G | |||

| PHSG | ○ | 2300℃ | 10-3Pa~0.9MPa・G | ||||

| PHS | ○ | ○ | 2300℃ | 10-3Pa~0.9MPa・G | |||

| VHS | ○ | ○ | ○ | 2300℃ | 10-3Pa~atmospheric pressure | ||

| VESTA | ○ | ○ | ○ | ○ | 2300℃ | 10-3Pa~0.9MPa・G | |

| PVSG | ○ | ○ | ○ | ○ | ○ | 2300℃ | 10-3Pa~0.9MPa・G |

| VHP | ○ | ○ | 2300℃ | 10-3Pa~atmospheric pressure | |||

| VHB | ○ | 1350℃ | 10-3Pa~atmospheric pressure | ||||

| VHD | ○ | ○ | ○ | ○ | 1000℃ | 10-1Pa~atmospheric pressure | |

| PHP | ○ | 2300℃ | 10-3~0.9MPa・G | ||||

| PHG | ○ | 1350℃ | 10-3~0.6MPa・G | ||||

| VHL | ○ | ○ | ○ | ○ | 2300℃ | 10-3~atmospheric pressure | |

| PHL | ○ | ○ | ○ | ○ | 2300℃ | 10-3~0.9MPa・G | |