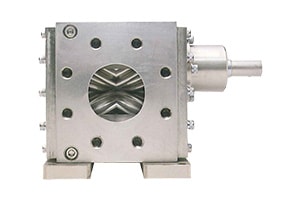

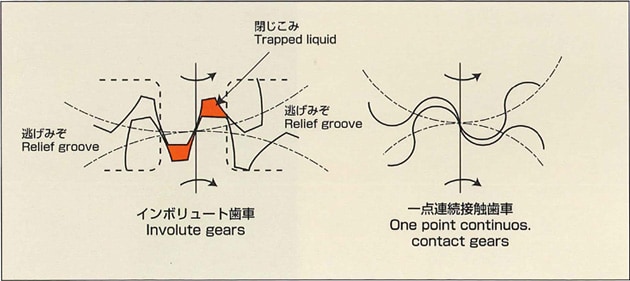

SX (SD) series Shimacloid gear pumps are equipped with Shimacloid gears for their essential internal gears.Shimacloid gears always maintain a continuous single-point contact tooth profile, based on an entirely new profile analysis theory. Since these teeth are never in contact at more than a single point, there is no gear slippage or trapping of liquid in the engaged sections of the gears, as is typical with involute gears. While SX series pumps were designed to be kept in standard inventory for standard all-purpose use, special-order SD series models equipped with Shimacloid gears are also available to meet a wide variety of specialized customer requirements. For further information about SD series pumps, please contact your local Shimadzu representative.

Tooth Profile Comparison

Features

- No slippage at the gear contact point allows austenite stainless steel to be used as the gear material.

- Suitable for non-pulsed output.

- High-speed rotation allows a smaller pump to provide the required flow rate. Simplified pump design reduces pump weight approximately 25%, compared to standard pumps.

- Easy to maintain.

- Heating or cooling jacket can be used.

- Single mechanical shaft seal is standard equipment, however, 3 other types of shaft seals can also be used.

Applications

- Synthetic fibers and resins

Acrylic, viscose, acetate, film raw material liquids, polyvinyl chloride, vinyl acetate, styrene (RDM), unsaturated polyester, artificial leather, hydrocarbons, carbon fiber and others - Food products

Molasses, candy, millet jelly, and others

Specifications

| Suction Pressure | -0.1 to 1 MPaG (full vacuum to 10 kgf/cm2G) |

|---|---|

| Discharge Pressure | 2 MPaG (20 kgf/cm2G) Max. 2.5 MPaG (25 kgf/cm2G) |

| Capacity | 2 to 300L/min |

| Viscosity | 0.03 to 1000Pa·s (0.3 to 10000 poise) |

| Temperature | 0 to 100°C |

| Jacket Pressure | 0.5 MPaG (5 kgf/cm2G) |

Pump Models

| Pump Model | Suction Flange | Discharge Flange |

|---|---|---|

| SX50 | SAE SPLIT FLANGE 50A | SAE SPLIT FLANGE 50A |

| SX100 | SAE SPLIT FLANGE 65A | SAE APLIT FLANGE 65A |

| SX250 | JIS20K, 80A, F.F | JIS20K, 80A, F.F |

| SX400 | JIS20K, 100A, F.F | JIS20K, 100A, F.F |

| SX630 | JIS20K, 125A, F.F | JIS20K, 125A, F.F |

| SX1000 | JIS20K, 150A, F.F | JIS20K, 150A, F.F |

For further details or inquiries regarding SD series pumps, contact us.

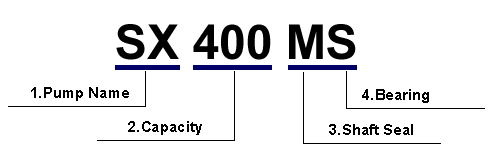

MODEL

| 2.Capacity | 50: 50 cm3/rev 100: 100 cm3/rev 250: 250 cm3/rev |

400: 400cm3/rev 630: 630 cm3/rev 1000: 1,000 cm3/rev |

|---|---|---|

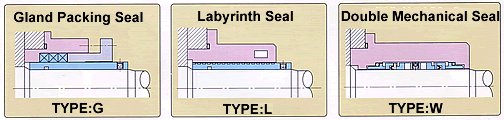

| 3.Shaft Seal | M: Single Mechanical Seal G: Gland Packing Seal |

L: Labyrinth Seal W:Double Mechanical Seal |

| 4.Bearing | S: Special Steel | A: AI-SN Alloy Steel |

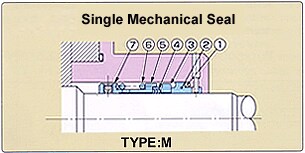

Shaft Seal

Design of Standard Single Mechanical Seal

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| Description | O-ring | Seat | Primary ring | V-packing | Retainer | Spring | Collar |

Additionally, any of 3 other types of shaft seals can be used. Let Shimadzu help you select the most appropriate seal for your operation conditions.

Since drive shaft design is the same for all 4 types of pump shafts, easily change the shaft seal by simply changing the seal parts and stuffing box.