November 6, 2023 | News & Notices R&D on Social Implementation of Cultured Wagyu Beef Selected for Promotion Under NEDO’s Project for Development of Innovative Biomanufacturing Technologies

Fujimori Kogyo Co., Ltd. (ZACROS)

TOPPAN Holdings Inc.

Shimadzu Corporation

A joint proposal for research and development on the social implementation of cultivated wagyu beef, submitted by Fujimori Kogyo Co., Ltd. (ZACROS), TOPPAN Holdings Inc. (TOPPAN Holdings), and Shimadzu Corporation (Shimadzu), has been accepted by Japan’s New Energy and Industrial Technology Development Organization (NEDO) and earmarked for implementation by the three companies under NEDO’s program for the development of innovative biomanufacturing technologies.

Biomanufacturing involves the use of cutting-edge biotechnologies to increase production capacity for materials conventionally produced by microorganisms, to gain the ability to produce new target materials, or to obtain target materials through processes such as enzymatic decomposition. Such manufacturing techniques are expected to be applicable not only in pharmaceuticals and food production, but in a variety of other fields as well, including chemicals, materials, textiles, and fuel.

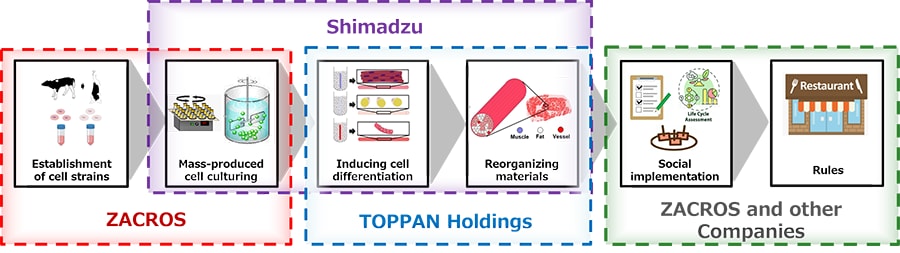

ZACROS, TOPPAN Holdings, and Shimadzu have decided to harness their combined knowledge and technologies to pursue research and development focused on the first social implementation of cultured Japanese wagyu beef. Cultured meat is made by culturing animal cells. This project will research the mass production technologies needed for a stable supply of cultured cells, edible cell culture media, and edible non-cellular biomaterials, and it will also develop the means of evaluating the social implementation of cultured meat, i.e., how cultured meat can be introduced to and accepted in society as a whole. Research and development will be conducted nationwide in collaboration with Osaka University, the University of Tokyo, Tokyo Women's Medical University, Tokyo University of Agriculture, and the Japan Association for Cellular Agriculture (JACA).

The three companies aim to develop the technologies needed to provide cultured meat by 2025. The next step will be to establish the technologies necessary for 2,000-L scale mass cell culture production by the end of fiscal 2027, and to significantly reduce the cost of producing edible cell culture media. In order to encourage the introduction of cultured meat to society at large, the companies aim to have cultured meat production operations online by 2029 and to commercialize that operation by 2031.

The research will be conducted from fiscal 2023 to fiscal 2027 and will delve into the following four themes.

- Development of mass production cell culturing technologies to ensure a safe and stable supply of the cells needed to create cultured meat (Led by ZACROS)

- Production of edible cell culture media and reduction of costs (Led by Shimadzu)

- Development of non-cellular edible biomaterials and the required production processes (Led by TOPPAN Holdings)

- Development of evaluation methods and other mechanisms needed for social implementation – introducing cultured meat to society (Led by ZACROS and other companies)

R&D system for social implementation

About the three companies involved in the project

ZACROS

Fujimori Kogyo Co., Ltd., which is known by the brand name ZACROS, has helped develop technologies for the culturing of animal cells as a member of the Manufacturing Technology Association of Biologics (MAB), and collaborates with Professor Masahiro Kino-oka of Osaka University’s Department of Biotechnology in the Graduate School of Engineering, Kotozukuri Consortium for Cell Manufacturability. These efforts have helped ZACROS achieve mass culturing of human cells for use in regenerative medicine (100-L culturing of human mesenchymal stem cells and 10-L culturing of human iPS cells), and it has promoted the scaling-up of production and implementation of mass production capabilities. ZACROS launched a cell culturing contract business in June of this year.

ZACROS has also collaborated with Japanese government agencies in regard to the single-use bags required in biomanufacturing. The company received support from the Ministry of Economy, Trade and Industry (METI)1 to bolster production capacity and from the Ministry of Health, Labour and Welfare (MHLW)2 to enhance its development capabilities. These efforts and achievements will be leveraged in the project with TOPPAN Holdings and Shimadzu to accelerate development of mass cell culturing technologies capable of safely producing the cells needed as raw material in the production of cultured meat. As project lead, ZACROS will be responsible for coordinating implementation with TOPPAN Holdings, Shimadzu, and other collaborators in the research. The aim is to introduce cultured meat on a societal level, and ZACROS will advance various initiatives to achieve that, focusing on areas such as safety and labeling rules for brand-building, Life Cycle Assessment (LCA), and improving market receptivity to cultured meat.

- 1. Selected to receive support as a project to develop biopharmaceutical manufacturing sites to strengthen vaccine production.

2. Selected to receive support as a project for urgent improvement of vaccine manufacturing systems.

TOPPAN Holdings

TOPPAN Holdings has been conducting joint research with Osaka University’s Graduate School of Engineering since 2017 and has developed a proprietary 3D cell culture technology called invivoid™. In the process of working on controlling and organizing various cells, TOPPAN Holdings and Osaka University have succeeded in making a biomaterial into an ink and 3D printing various types of fibrous tissue, such as muscle, fat, and blood vessels. In the research with ZACROS and Shimadzu, TOPPAN Holdings will use this technology to verify the cultured meat production process and develop edible bio-ink. TOPPAN Holdings will also work on building the societal culture and systems needed to encourage early formation of a market for foods produced by cell culture.

Shimadzu

Shimadzu provides chromatographs, mass spectrometers, and a variety of other analytical and measurement instruments and technologies. In recent years, the company has also focused on the development of equipment and technologies that harness AI and robotic technologies to automate the cell culturing process and make it more efficient. Shimadzu uses its knowledge through the Future Creation Consortium for Cultured Meat™, founded with collaborators such as Osaka University’s Graduate School of Engineering, Itoham Yonekyu, Toppan (now TOPPAN Holdings), and Sigmaxyz, to develop automated cultured meat production equipment using 3D bioprinting technologies.

In addition, at the Osaka University Shimadzu Analytical Innovation Research Laboratories, Shimadzu is researching analytical and measurement technologies for use in cultured meat development. In the research with ZACROS and TOPPAN Holdings, the company will use the regenerative medicine culture media technologies developed by Shimadzu Diagnostics Corporation, which became a wholly owned subsidiary in 2022, to create edible culture media and reduce costs.