3-2) Solvent Delivery Malfunctions Due to Bubbles Generated Inside the Pump

Problems with Formation of Bubbles in Flow Lines

Solvent Delivery Malfunctions Due to Bubbles Generated Inside the Pump

Even if the dissolved air in the mobile phase bottle is below the saturated solubility level, bubbles can still form when the solution passes through the pump.

(1) Low-Pressure Gradient Mixtures: When different solvents are mixed at atmospheric pressure (or slightly lower pressure), then bubbles can form in the area circled in red in Figure 10, due to the mechanism described in 2-3). No matter how far downstream (high pressure side) from the pump the gradient mixer is installed, mixing will begin in the area circled in red, which will cause some degree of bubble formation to occur. In contrast, in high-pressure gradient mixing, mixing begins downstream (high pressure side) from the pump, so this sort of problem does not occur.

(2) Suction Filter Clogging: If the suction filter becomes clogged, resistance increases during suction, increasing the likelihood of bubble formation due to the pressure drop within the filter. Clogging can occur in cases such as when the filter is left idle and foreign matter adheres to it or when methanol is passed through the filter without realizing the previous mobile phase was a buffer solution. If the degree of clogging is light, air bubbles can be prevented by adequately degassing the mobile phase, but this is actually a problem that should be resolved by cleaning or replacing the filter.

The problems that can be caused by these factors are the same as described in 3-1).

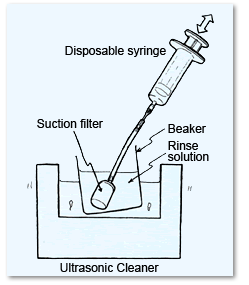

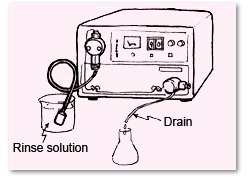

How to Clean Suction Filters

If a suction filter becomes clogged with insoluble matter or debris, try reverse-flow rinsing it in an ultrasonic cleaner, as shown in Figure 11. If clogged by compound precipitation, rinse the filter by switching rinse solutions, in order, from water to solution A to isopropyl alcohol and to chloroform (where, A is a dilute aqueous ammonia/methanol solution in the case of an acidic organic compound or dilute aqueous phosphoric acid/methanol solution in the case of a basic organic compound). In addition, use the pump for thorough rinsing (Figure 12). Even after rinsing, if bubbles appear in the suction tube during fast flow_rates, replace the filter.

Note that a dilute nitric acid solution (do not let it contact alcohol) is often used as the rinse solution for metal particles, while aqueous EDTA-2Na solution is often used for metal ions and aqueous SDS solution is often used for proteins.

Fig. 10 Low-Pressure Gradient Mixing

Fig. 11 Cleaning Suction Filters

Fig. 12 Cleaning Suction Filters

|

Note: |

This page is a partially revised html version of LCtalk Special Issue 5 (1991). |