Vol.11 Issue 2 / Latest topics 3From Lab to Kitchen: Cultured Marbled Meat Featured at Osaka-Kansai Expo 2025

-

As a member of the Consortium for Future Innovation by Cultured Meat, Shimadzu co-hosts an exhibit of real cultured meat and a Meat Maker unit at the Expo 2025 Osaka, Kansai, Japan (hereinafter “EXPO 2025”).

Cultured Meat as a Potential Solution to Social Issues

According to the United Nations estimates, the world’s population is expected to reach almost 10 billion by 2050. As the demand for protein increases on the back of population growth and dietary changes, the resources required to raise livestock are in short supply. It has been said that within several years to several decades, humanity will face a “global protein crisis” triggered by a breakdown in the supply and demand of protein.

Cultured meat is one type of meat alternative that is produced by culturing cells harvested from animals. This concept of culturing cells is what differentiates cultured meat from other meat alternatives. Cultured meat represents a potential solution to food supply and environmental issues.

Leveraging 3D Bioprinting Technology to Produce Cultured Meat Similar to the Real Thing

The Consortium for Future Innovation by Cultured Meat that hosts the cultured meat exhibit at EXPO 2025 was established in 2023 by the Graduate School of Engineering, The University of Osaka,Shimadzu Corporation, Itoham Yonekyu Holdings, Inc., Toppan Inc.(currently Toppan Holdings Inc.), and SIGMAXYZ Holdings Inc. The Consortium aims to promote practical initiatives for the social implementation of 3D bioprinted cultured meat production technology. With the recent addition of ZACROS Corporation to the Consortium, a total of six parties are now actively involved in promoting this initiative.

-

The Consortium for Future Innovation by Cultured Meat’s exhibition booth in the Osaka Healthcare Pavilion

The Consortium for Future Innovation by Cultured Meat’s exhibition booth in the Osaka Healthcare Pavilion

The Consortium for Future Innovation by Cultured Meat’s exhibition booth in the Osaka Healthcare Pavilion

The Consortium for Future Innovation by Cultured Meat’s exhibition booth in the Osaka Healthcare Pavilion

Cultivated meat on display at the “Homemade Marbled Meat” exhibit in the Osaka Healthcare Pavilion

Cultivated meat on display at the “Homemade Marbled Meat” exhibit in the Osaka Healthcare Pavilion

-

The 3D bioprinting technology developed by Professor Michiya Matsusaki (Division of Applied Chemistry, Graduate School of Engineering, The University of Osaka) cultures the muscles, fat, and blood vessels of harvested animal cells and then combines each fiber in a similar arrangement to that of actual meat. This technique makes it possible to reproduce the marbling of real meat resulting from intramuscular fat in red meat.

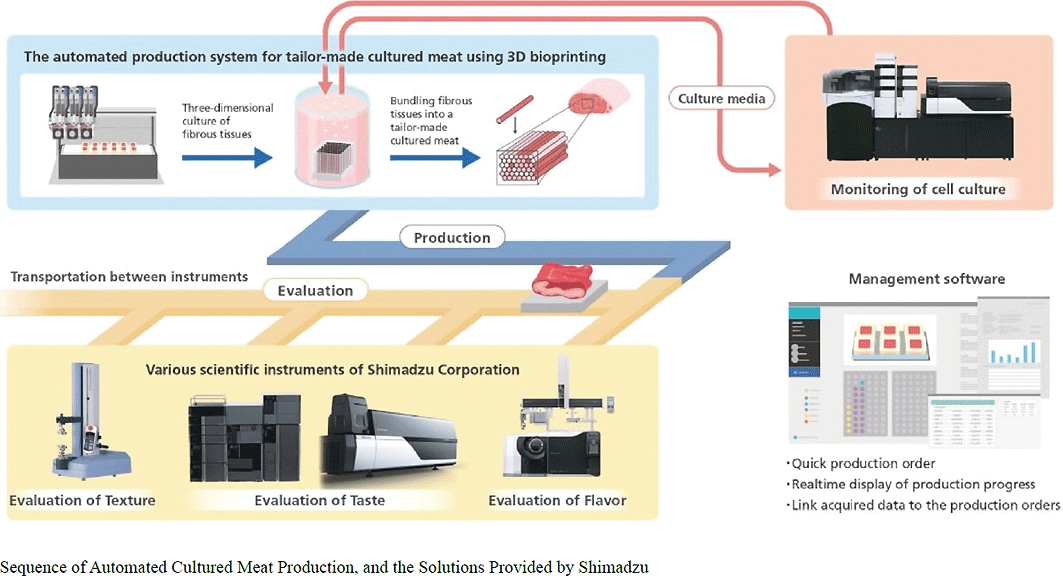

Shimadzu’s role in the Consortium involves developing an automatic cultured meat production unit capable of automating and streamlining the cell culture process, making the culture medium edible and reducing costs by leveraging our culture medium production expertise,and analyzing and evaluating the deliciousness of the cultured meat including its taste and aroma. The automatic cultured meat production unit is the world’s first instrument to automate the process of forming a steak by bundling fibers of muscle, fat, and blood vessels with 3D bioprinting technology.Experience the “Future Kitchen” at Expo 2025

The Consortium for Future Innovation by Cultured Meat is a premium partner of Expo 2025’s Osaka Healthcare Pavilion. The Cities in the Future area within this pavilion features an exhibit of actual cultured meat and a conceptual model of the Meat Maker (the cultured meat production unit) using 3D bioprinting technology.

The concept of this exhibition is “From ‘store-bought meat’ to‘homemade meat’.” The exhibition expresses the image of the “future kitchen” in which “everyone has a meat maker in their home that can create marbled steaks tailored to the health and preferences of the individualconsumer through a range of options, including the type of meat and the desired nutrients from iron, vitamins, minerals, and dietary fiber. We are also planning to host an event on the Reborn Stage of the Osaka Healthcare Pavilion on July 8 where visitors can experience the aroma of cultured meat.From Cultivation to Taste Evaluation

While research is continuing into the mass production of cultured meat,Shimadzu’s goal is to create tasty cultured meat as close as possible to Wagyu beef. Shimadzu also has solutions related to how the food tastes.

For example, Shimadzu provides small bench-top testing machines for quantifying food texture including the tenderness and chewiness of cultured meat; liquid chromatographs (LC) and liquid chromatograph mass spectrometers (LC-MS) for measuring the types and amounts of amino acids, vitamins, and other taste-related ingredients; and gas chromatograph mass spectrometers (GC-MS) for measuring the types and amounts of ingredients responsible for aroma and flavor. The deliciousness of cultured meat is being evaluated using a variety of approaches.

In the future, as technological developments progress, it will become possible to adjust the ingredients of the meat produced to suit individual tastes and health profiles. We are likely entering an era in which the balance of fat and lean meat of delicious Wagyu beef is customized to our liking.