Aromas

In evaluating the tastiness of food, important factors include the five flavors sensed by the tongue (sweetness, saltiness, sourness, bitterness, and umami), as well as spiciness, astringency, and even aroma. The freshness of food products is another important element from the perspective of quality control since it is a sensitive indicator of tastiness.

A huge number of components contribute in complex ways to the human sense of aroma and off-flavor, so sensory testing, which allows for comprehensive evaluation, is widely used.

At the same time, using analytical instruments, many substances responsible for aromas and off-flavors can be detected and identified, and their concentrations checked.

In addition, analysis of the data obtained makes it possible to identify the components contributing to the aroma and off-flavor, thereby complementing sensory testing and enabling the objective quantification of aromas and off-flavors.

- Example of the Introduction of

Such Tests: Quality control

- HS-20 NX+

GCMS-QP2020 NX

Aroma Component Analysis

Smart Aroma Database

Routine Analysis

Confirmation of Known Components

- Example of the Introduction of

Such Tests:研究・商品開発

- AOC-6000 Plus+

GCMS-QP2020NX

Routine Analysis, Quantification of

Known Components/Quality ControlHeadspace (HS) Method + GC-MS (/MS)

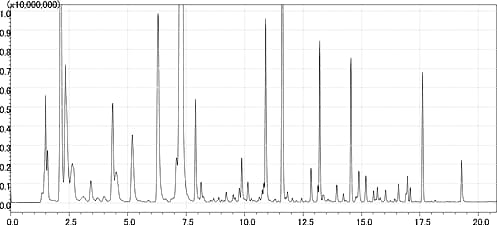

HS-GC/MS (/MS) is ideal for analyzing high-concentration samples and known components. In a headspace sampler, a sample sealed in a vial is warmed for a certain period, causing the gas phase and the sample to come into equilibrium. The gas phase component (headspace) is then injected into a gas chromatograph (GC) for analysis.

A wide range of samples, including liquids and solids, can be analyzed, no particular pretreatment is required, and the instrument is simple to operate, so it is widely used for quality control. The Trap HS method uses an electronically cooled trap to concentrate the sample, enabling the high-sensitivity analysis of trace amounts of aromas and off-flavor components. Here, we look at one example of analyzing the aroma components in beer for quality control using the HS-GC/MS method and the Smart Aroma Database, which includes the conditions for measuring over 500 components important for aroma.

Headspace (HS) Method + GC-MS (/MS)

(Syringe System)

In a headspace sampler, a sample sealed in a vial is warmed for a certain period, causing the gas phase and the sample to come into equilibrium. The gas phase component (headspace) is then injected into a gas chromatograph (GC) for analysis. A wide range of samples, including liquids and solids, can be analyzed, no particular pretreatment is required, and the instrument is simple to operate, so it is widely used for quality control. The Trap HS method uses an electronically cooled trap to concentrate the sample, enabling the high-sensitivity analysis of trace amounts of aromas and off-flavor components.

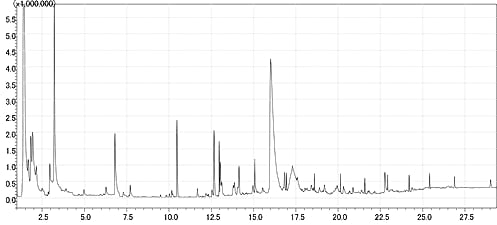

Trace Component Measurement,

Investigation/Research and DevelopmentSolid Phase

Micro Extraction (SPME) Method + GC-MS/MS

This section introduces the SPME-GC/MS (/MS) method, which is ideal for measuring components present in trace amounts and for the highly selective and sensitive measurement of target components. By concentrating volatile components on the SPME fibers, the fast, convenient, and high-sensitivity measurement of trace components can be achieved. This makes it effective for research, including the search for components that contribute to aromas. Used in combination with the Smart Aroma Database, which has the measurement conditions for more than 500 important aroma compounds, the SPME method can also be used in research and development.

Solid Phase Micro Extraction (SPME) Method + GC-MS/MS

This method concentrates volatile components in SPME Fibers, and the sample is injected into a GC/GCMS. Compared to other sample injection methods, this is faster and easier, and the volatile compounds can be concentrated without solvents. In SPME Arrow, the latest in SPME technology, the fibers are coated with a larger volume of adsorbent compared to conventional SPME fibers, allowing for highly sensitive analysis. Further, its thick and sturdy structure boasts high durability.

Aroma Component AnalysisSmart Aroma Database: A Database for Aroma Analysis

There are a huge number of substances that contribute to aromas. Establishing the measurement conditions for these and identifying the contributing components from the vast amounts of measurement results is costly and labor intensive. The Smart Aroma Database contains analysis and compound information for more than 500 components that are important for aroma. Using retention times, characteristic ion and mass spectrum information, even aroma components that are difficult to analyze using conventional comprehensive analysis methods can be detected reliably and efficiently.

A Database Designed for Aroma Components Searches

- (1) High-accuracy automatic detection of aroma components from scan measurements

- The database stores information required for the analysis of 511 important aroma components.

- (2) Easily narrow down the compounds that contribute to aromas.

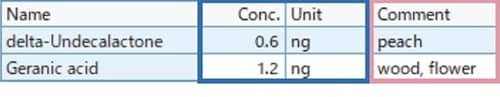

- Sensory information about registered compounds and semi-quantitative functions enable data analysis of the compounds that contribute to the aroma.

- (3) Supports high-sensitivity target analysis using MRM and SIM

- Create highly sensitive methods for targeted analysis in MRM and SIM modes without the use of standard samples.

- (4) Compatible with a variety of systems for aroma analysis

- Various samplers and odor-sniffing GC-MS systems used in aroma analysis are supported.

The quality and intensity of the odors can be used to identify the components

that contribute to the aroma of the compounds detected.

- Note:

-

- Semi-quantitative results may differ from the actual values depending on the condition of the instrument. In addition, the pretreatment extraction efficiency is not taken into account, so the results will differ depending on the pretreatment device used. If accurate quantitative results are required, be sure to conduct quantitative tests using standard samples.

- Note: Semi-quantitative functions are not supported by the HS-20 series.

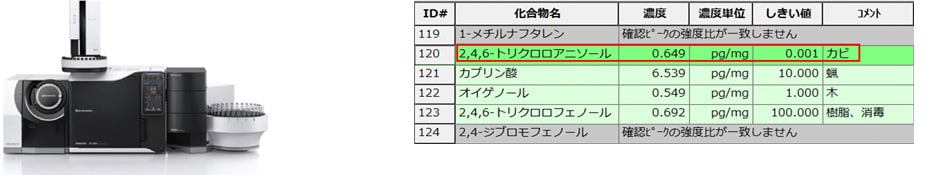

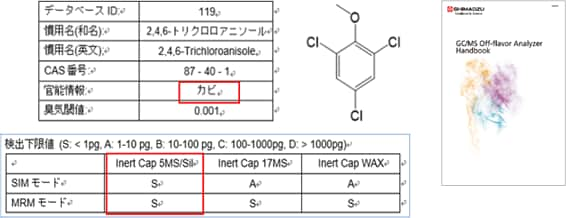

Off-Flavor AnalysisOff-Flavor Analysis System

In order to resolve off-flavor issues, the substances responsible must be identified. However, accurate identification knowledge and experience are required, such as knowing what components cause off-flavor, the quality of the odor and how to determine their threshold values. The GC/MS Off-Flavor Analysis System contains a database preregistered with the parameters required for analysis and information (such as odor quality and odor threshold values) about the main off-flavor-causing substances. Accordingly, off-flavor analyses can be performed easily, even by users with no knowledge or experience with this type of analysis.

A Database Designed for Aroma Components Searches

- Components detected in past off-flavor cases are specified in a database.

- Analysis methods are created automatically using preregistered retention indices. (No standard samples are required.)

- Sensory information (odor quality and odor thresholds) for off-flavor components are preregistered.

Confirmation of the odor of off-flavor items

Select column

Set instrument information and analysis

Compare concentration with the off-flavor threshold