Recycling Resources

Promoting Proper Waste Disposal and Recycling

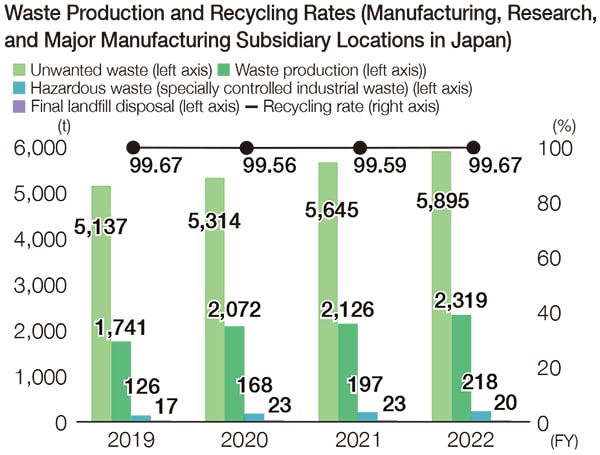

In part due to performance growth in the analytical and measuring instruments and industrial machinery segments during FY 2022, the total amount of unwanted waste (the total of waste materials for disposal and metal scrap and other valuable materials for resale) from key Shimadzu business and research facilities in Japan increased by 4.4% (year-on-year) to 5,895 tons. The total amount of waste materials for disposal increased by 9.1% (year-on-year) to 2,319 tons. Of these amounts, industrial waste from products using plastics was 483.3 tons (117% compared to 412.9 tons in the previous year). Although we failed to achieve our goal of reducing waste to below the previous year’s level due to the increase in packaging-related waste from higher production, we have been promoting initiatives such as material recycling of plastic packaging materials.Shimadzu’s waste management goal is to achieve a recycling rate of at least 99% (= (amount of unwanted waste - amount of final landfill disposal) / amount of unwanted waste).The recycling rate in FY 2022 was 99.67%, which was achieved for 13 consecutive years.The Shimadzu Group is committed to compliance with laws and regulations and the promotion of the 3Rs (Reduce, Reuse,Recycle) in each workplace in order to make effective use of the earth’s limited resources and contribute to building a recycling-oriented society. We have also established and implemented internal rules and procedures to ensure legal compliance, such as appointing eco/industrial waste leaders at each workplace to promote waste separation and recycling,manage manifests,and conduct investigations, including on-site visits of waste disposal contractors.

Upcycling Packaging Materials into Polyethylene Containers for Waste Liquid Collection

Shimadzu recycles its waste plastic packaging materials into containers for collecting waste liquids to promote resource circulation and environmental sustainability. This is being done in cooperation with local communities and has been adopted and implemented by the FY 2022 Kyoto Prefecture 3R technology development support project (in the research and technology development field).

In FY 2022 we collected used plastic packaging materials and worked with a partner company to produce 1,000 polyethylene containers made from 30% recycled pellets for in-house use.

This initiative, which was a shift to material recycling to improve the quality of resource recycling, has led to collaboration with academic and research institutions that generate large amounts of liquid waste. We have concluded a“ Comprehensive Collaborative Agreement” with Ryukoku University to contribute to the creation of a recycling-oriented society, and the university will participate in this initiative.

In the foreground is a polyethylene container made of 30% recycled pellets

Waste Plastic Collection System Using IoT Technology

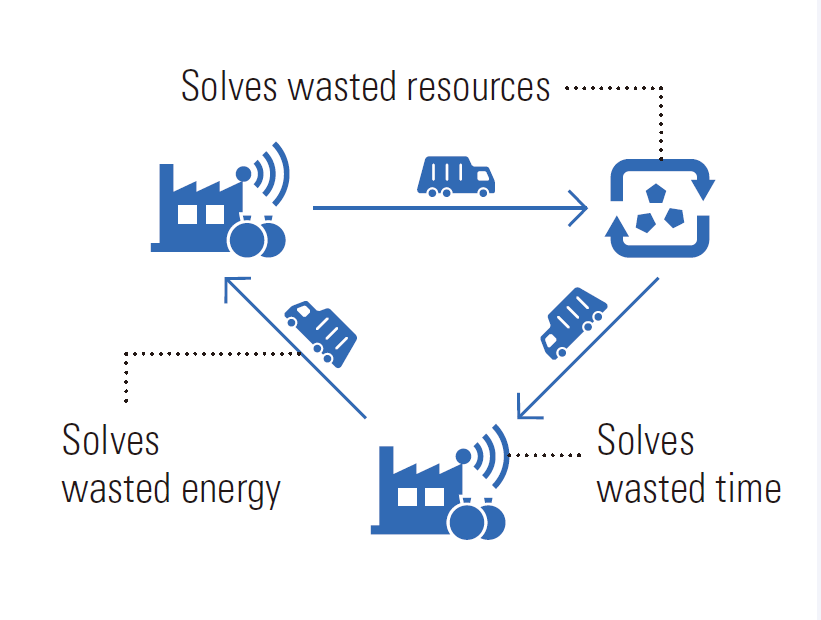

A system to automatically collect plastic waste generated from plants was introduced in January 2020 to increase recycling rates and reduce CO2 emissions. Currently, the systems have been introduced at five locations within and outside Shimadzu in cooperation with suppliers, including at Sanjo Works and Seta Works, which have high plastic waste output levels.

Using IoT technology means waste management companies can determine the quantity of waste stored at each site in real time without having to travel to the site. Consequently, they can collect waste from multiple sites at more appropriate times to increase loading efficiency, reduce travel distances, and help increase supplier recycling rates. In the future, we intend to further contribute to environmental conservation by expanding the introduction of the systems within the Shimadzu Group and achieving widespread use in society.

This initiative is a Kyoto Prefecture demonstration project, in which Shimadzu was a participant and which received the ICT Regional Revitalization Award 2019 from the Japanese Ministry of Internal Affairs and Communications.

Shows waste quantities in real time Collection

efficiency improved by collecting from multiple sites

Sensors Installed (on ceiling) at Waste Collection Areas

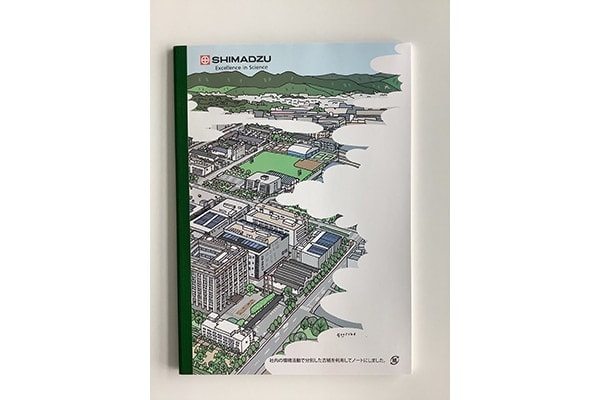

Recycling of Paper Waste

One of the environmental activities that all employees can participate in is sorting paper waste from offices and plants. Sorted and collected paper waste is recycled into unique notebooks for reuse by employees. Having employees experience the benefits of environmental activities in such a tangible way helps them become more aware of environmental activities.

The Handling of PCBs

Transformers, capacitors, and other devices containing highly toxic PCBs (polychlorinated biphenyls) are disposed of in accordance with the Japanese Act on Special Measures Concerning Promotion of Proper Treatment of PCB Wastes. (PCBs are particularly toxic to biological organisms because they are highly persistent and bioaccumulative.) Of the PCB waste materials owned by Shimadzu, Shimadzu started processing transformers and capacitors, which contain high PCB concentrations, in FY 2013 and will finish processing all the PCB waste within the time frame specified in the Japanese Act on Special Measures Concerning Promotion of Proper Treatment of PCB Wastes.

Meanwhile, Shimadzu Techno-Research Inc., a Shimadzu Group company, offers an easy method for analyzing the quantity of trace PCBs in two types of insulating oil. This measurement technology is able to quickly and inexpensively provide highly reliable measurement values and was even included in the Manual for Simplified Measurement of Trace PCBs in Insulating Oil (3rd edition), published by the Japanese Ministry of the Environment in May 2011.

Promoting Environmentally-Friendly Packaging

Shimadzu Logistics Service Corporation is engaged in a wide variety of activities for environmental conservation within its logistics activities. Of these, they are currently focused on switching to more environmentally-friendly packaging materials. Previously, heavy items were typically packed in crates made of lumber and plywood, but now they are switching to reinforced corrugated cardboard. The environmental benefits of switching to reinforced corrugated cardboard include conserving wood resources and reducing CO2 emissions during transport or incineration of the packaging materials. If wood materials are used, materials from Forest Stewardship Council-certified forests are recommended as a measure to promote biodiversity.

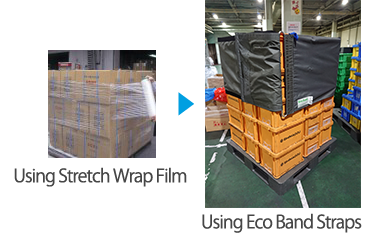

Furthermore, in an effort to reduce the amount of stretch wrap film (plastic) used to prevent loads from falling during transit, they started using reusable and efficient Eco Band pallet straps. Using the Eco Band straps has reduced the amount of plastic waste by 460 kg in FY2020.

We intend to continue activities in the logistics field that help conserve the environment.

At a Shimadzu Group company in the UK, employees have been actively involved in implementing environmentally-friendly reusing practices. One such measure is the “reusable supplier delivery container project,” which involves using reusable packing boxes to transport purchased parts or service parts from suppliers. The container was designed in cooperation with suppliers based on operations during production. Using the containers, which are designed specifically for packing the given parts, offers a wide range of benefits, such as reducing expenses from damage during transit and from less disposable corrugated fiberboard box waste.

Independently Designed Supplier Delivery Containers