Operation of Hisaki Spectroscopic Planet Observatory Satellite Ends

Ten Years of Contribution by Shimadzu's Diffraction Grating

In December 2023, the spectroscopic planet observatory satellite, Hisaki, ended its 10-year term of duty. The heart of the spectrometer required for observations is a diffraction grating developed by Shimadzu Corporation.

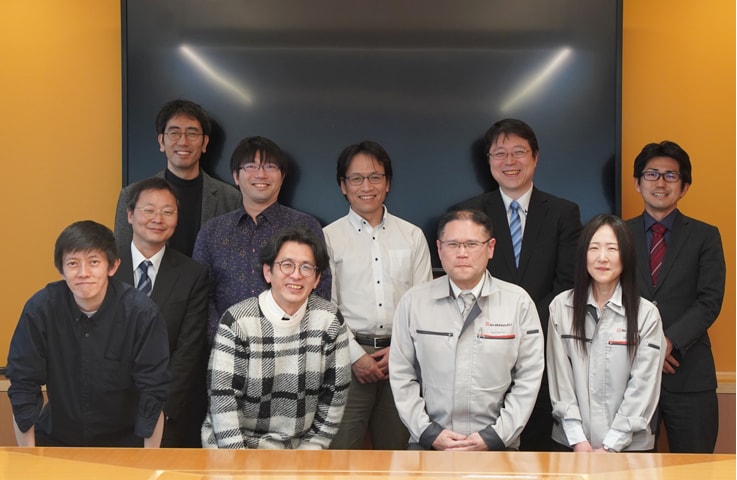

JAXA and university researchers and Shimadzu personnel. Reflected on the 15-year Hisaki project and thanked each other

In March 2025, six researchers from the Japan Aerospace Exploration Agency (JAXA), The University of Tokyo, Tohoku University, and Rikkyo University visited Shimadzu Corporation to report to Shimadzu employees on the accomplishments of the Hisaki and announce the concept for developing the next-generation model. In addition, they interacted with original development team members and other Shimadzu personnel who launched the project 15 years ago.

- Shimadzu’s Diffraction Grating Supported

Observations for Determining the Origins of Planets - Shimadzu Started Manufacturing Diffraction Gratings, Optical Devices that Shine Like a Rainbow, 50 Years Ago

- Developed from a Singular Determination to Satisfy Customer Needs

- Taking on the Challenge of our First Space Project Led to a Series of Difficulties

Shimadzu’s Diffraction Grating Supported

Observations for Determining the Origins of Planets

JAXA researcher presentations at Shimadzu Corporation

It is said that when the solar system was initially formed, Venus and Mars were very similar to Earth, with plenty of air and water. However, several billion years ago, Venus changed to become a scorching hot planet with surface temperatures over 450 ℃ and Mars a freezing cold planet with temperatures below -50 ℃.

What caused such a big temperature difference? Why is Earth the only place in the big universe with an environment that can support life? Maybe if we could answer those questions, we could talk about what the Earth will look like in the distant future. That is some of the thinking by researchers that inspired launching Hisaki into space.

Hisaki is the world's first space telescope intended for planetary observation that is equipped with an extreme ultraviolet spectrometer developed by JAXA. Though referred to as a telescope, Hisaki does not actually obtain photographic images of planets. It is limited to investigating the atmospheric and magnetic field properties of target planets by spectrometric spectral measurements. Shimadzu’s Device Department was the organization in charge of developing the diffraction grating, which is the key device in the spectrometer.

Shimadzu Started Manufacturing Diffraction Gratings, Optical Devices that Shine Like a Rainbow, 50 Years Ago

Diffraction gratings are optical elements that are essential for technologies used to separate (monochromate) light into its respective wavelengths. Monochromation is an analytical technology that is essential not only for chemistry, biology, and other research, but is also crucial for achieving advancements in a wide range of other industries, such as semiconductors, materials, lasers, and optical communications.

Manufacturing diffraction gratings requires very sophisticated processing technologies involved in baking a thin film onto a substrate and cutting micron-level (1/1000th millimeter) grooves. Shimadzu started working together with RIKEN, a National Research and Development Agency in joint research from about 1975, which resulted in creating and patenting new manufacturing techniques. Later, Shimadzu began manufacturing diffraction gratings independently. As diffraction grating manufacturing technologies improved, they progressed to becoming an essential component in Shimadzu's unique spectrometric systems.

Developed from a Singular Determination to Satisfy Customer Needs

Extraordinary specifications are required for diffraction gratings used in special circumstances of space. The target of Hisaki measurements is extreme ultraviolet light, which has wavelengths so short that they cannot be measured on Earth due to interference by the atmosphere. Even searching the entire world, finding a source for a diffraction grating that can monochromate such short wavelengths is not an easy matter. Therefore, day after day, diffraction grating manufacturers around the world were declining the Hisaki team’s request to develop such a diffraction grating.

The Hisaki project manager at the time, JAXA Associate Professor Atsushi Yamazaki recalled that “When we first contacted Shimadzu, rather than immediately turning us away at the door, Shimadzu asked to hear about the project. That was how the project started.”

The specifications for the diffraction grating to be installed in the Hisaki required baking a thin film applied by chemical vapor deposition (CVD) onto a special silicon carbide (SiC) substrate with an aspherical surface and then cutting 1800 grooves per millimeter. The groove width from peak to valley is only 0.556 µm*. Furthermore, strict smoothness requirements for reflective surfaces after grooves were also added. Yamazaki laughed as he recalled that “It was ridiculous to request specification levels that were not even measurable with normal verification tools.”

*1µm=0.001mm

Naotaka Murata, Deputy Manager, Industrial Sales Unit, National Sales Department, Sales & Marketing Division, Shimadzu Corporation

Naotaka Murata, the sales person assigned to the project at the time, laughed as he searched through old emails and said “The requirements definitely involved the highest difficulty level possible. Nevertheless, we had been instilled with the spirit of our founder, Genzo Shimadzu Sr., expressed as ‘We will manufacture whatever the customer requests.’ I recall that the team members, including myself, responded positively, saying, ‘Let’s try it first, and then we can talk about what to do if it fails.’”

Taking on the Challenge of our First Space Project Led to a Series of Difficulties

Hiroyuki Sasai, General Manager, Device Department, Shimadzu Corporation

They encountered a string of difficulties as soon as the actual development started. Sasai, who was the Chief Engineer at the time, reflected that “In addition to the difficulty of even ordering samples, even after they were created according to order, all sorts of problems occurred, such as not producing satisfactory data. Consequently, it took about a year and a half repeatedly creating and verifying prototypes before we were successful. However, that extra effort made the joy even greater when the Hisaki was finally launched into space.”

Hisaki was required to ensure a reliability of one year for moving parts and three years for non-moveable parts, but that resulted in obtaining continuous measurements in space for a much longer period of ten years. The number of scientific papers that have utilized Hisaki measurement data has reached 67 papers (including publications in Science and Nature Communications as of January 2025).

Atsushi Yamazaki said “Despite all our demanding requests to Shimadzu, they kept working with us and responded with technical expertise. The fact that they always seemed to be having fun at work made it easy to interact with each other. I still received the same impression during this visit, too. I hope Shimadzu never changes. To us, who are involved in creating unique one-of-a-kind spectrometers that cannot be found anywhere else in the world, we consider them a truly rare entity.”

In the back row, from the left, is Masato Kagitani, Assistant Professor at Tohoku University, Shingo Kameda, Professor at Rikkyo University, Go Murakami, Assistant Professor at JAXA, Fuminori Tsuchiya, Professor at Tohoku University, and Naotaka Murata and Yoshitaka Makino from Shimadzu Corporation.

In the front row, from the left, is Kazuo Yoshioka, Associate Professor at The University of Tokyo, Atsushi Yamazaki, Associate Professor at JAXA, and Hiroyuki Sasai and Yuki Oue from Shimadzu Corporation.

Page Title and URL Copied.

Page Title and URL Copied.