Vacuum Spray Method (work of approx. 5 litter)

- Vacuum inside of the test piece and spray helium gas on the outside surface of the work. If there is any leak point, helium will be detected from inside the test piece.

- Application: welded pipes, flexible tubes, hermetic seals etc.

Hood Method

- Wrap the test piece with hood. Vacuum inside of the test piece and inject helium gas in the hood. If there is any leak point, helium will be detected from inside of the test piece.

- Application: mass flow controller etc.

Sniffer Method (Optional sniffer unit is necessary)

- This method is used when it is not possible to vacuum the inside of the test piece for some reason. Put pressurized helium gas (or mixed gas with helium) inside of the test piece and sniff on the outside surface of the test piece. If there is any leak point, helium will be sniffed and detected.

- Application : compressors, radiators, condensers etc.

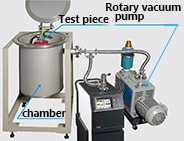

Bombing Method

(test chamber and bombing machine are necessary)

- This method is used to test leak of airtight parts. Inject helium gas in test piece with a bombing machine. Put the test piece in a test chamber of a helium leak detector and vacuum the chamber. If there is any leak, helium will leak from inside the piece and be detected.

- Application: crystal quarts, SAW filters etc.

※ Test chamber and bombing equipment are required.

Chamber Method

- Put the test piece, which has been filled with helium gas, in a bell jar or a chamber.

Vacuum the chamber or the bell jar with roughing vacuum pump and connect to a helium leak detector. Any leaks will allow helium to escape and be detected. - Application: fire extinguishers, air bag inflators etc.

Parallel Evacuation Method (The leak indicator unit is an option)

- For a huge chamber or test piece, use large roughing pumps to vacuum and detect helium gas exhausted.

- Application: vacuum vaporizing systems, absorption chiller, vacuum furnaces etc.

※ Wireless leak indicator is optional.