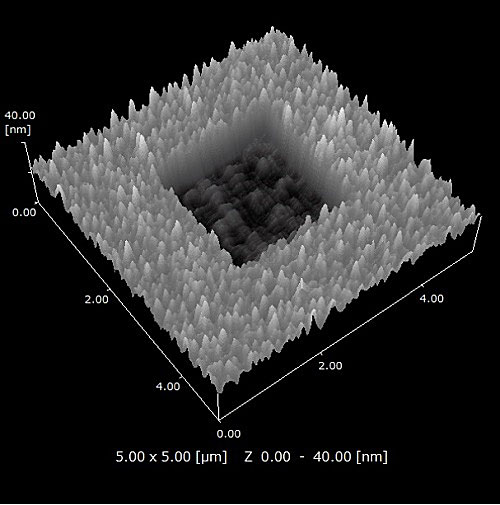

Observation Examples of Nanotechnology

Scratch on DLC Film

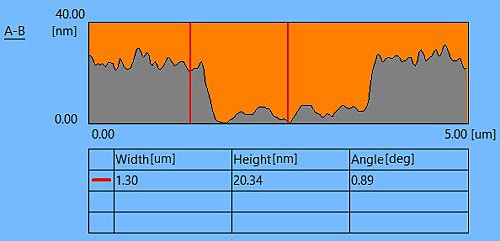

Measurement of 20 nm depth

using cross-section profile analysis

A rectangular scratch was made on the surface of a hard diamond-like carbon (DLC) film using a cantilever, and a depression 2 µm square and 20 nm deep was formed. The scratch conditions were adjusted by the cantilever spring constant and load, and the number of scans. The scan mode was LFM. In this example, a cantilever having a spring constant of 80 N/m and coated with DLC was used, a load of 30 µN was applied, and the 2 µm square area was scratched 4 times. The scan mode was then returned to normal AFM scan, and an area 5 µm square observed. The results are displayed by three-dimensional imaging and cross-sectional analysis.

Data provided by: Umehara Laboratory, Graduate School of Engineering, Nagoya University