AFM Ovservation of Coated Paper and Printed Surface

Introduction

Introduced in this article is observation of the condition of the surface of various printed matters by the atomic force microscope. A kind of printing paper was picked up as a sample, of which the coated surface where ink was not attached and the side with printing ink were three-dimensionally observed also. The coated surface was subjected to the measurement by the X-ray fluorescence spectrometer for the identification of the coating material. With respect to printing ink which is used in extremely diversified ways, it was observed only as one that could be discriminated from the other, not as identification of a certain kind.

As the result of the observation, it has been recognized that the AFM with the features of easy maneuverability and a 3D measurement function exhibits unique power unavailable from SEM and other. For example, metal coating, which is indispensable for the measurement of a sample without electrical conductivity as paper and ink by SEM, is not required, and for the judgement of surface roughness which is difficult by SEM, the AFM permits meticulours observation with an excellent 3D resolution.

AFM Observation of Coated Paper

Coating the surface of paper with white pigment, which has been adopted for a long time for enhancing the quality of printing, is an important method for improving the surface condition.

In this article, a certain kind of catalog paper was picked up as a material to be judged. It was a comparatively thick paper coated with a whit pigment mixed with tantalum, kaolin, and talc (revlealed by the X-ray diffractometer).

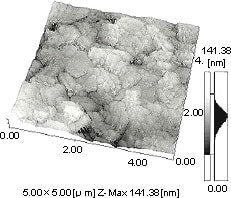

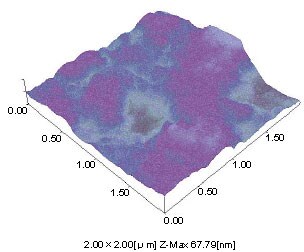

Fig.1 3D image of coated Paper

Fig.1 shows a 3D image of clay minerals like kaolin, As the image is constructed with high and low signals, it is possible to read height of an interested area by matching the brighness of the area with the corresponding scale at right.

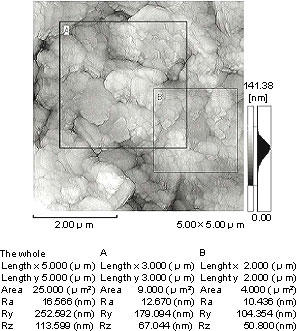

Fig.2 Surface Roughness of Coated Paper

Surface roughness is shown in Figure 2. Average roughness (Ra) and maximum roughness (Ry) are immediately output based on the 3D data. It was calculated that the mean roughness within 5 micron area was 16 nm, and the maximum was 252 nm.

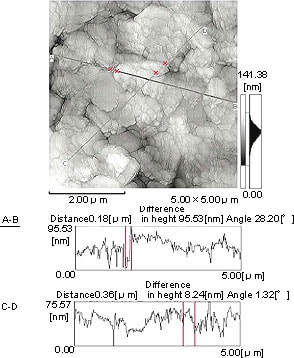

Shown in Figure 3 is a cross-sectional image of the coated paper. Arbitrary lines can be drawn on the image and the corresponding cross-sectional image can be observed. Here, it is read that the difference in level at the marked point on the line between A and B is 95 nm.

In the analysis introduced here, it took about 4-5 minutes for one sample for setting the sample through the acquisition of data, enabling micro information to be obtained in a comparatively short time.

The following are the features of the AFM that have been confirmed through the observation of the samples this time.

1. Direct observation is possible without pretreatment such as coating the sample

2. Condition of undulation on the sample surface can be clearly judged by a 3-D image.

3. There is no focussing work as required in SEM, etc.

4. With a viariety of image processing software available for it, it enables diversied information to be obtained.

Fig.3 Cross Sectional Measurement of Coated Paper

Among these date, what is worthy of notice most of all is the 3D image of 2: as image structure is made up of concave-convex signals, information on the topographic condition of the surface is also obtainable. It may be said that the AFM is a new type of microscope with new functions unavailable by an optical microscope or SEM.

AFM Observation of Printed Part

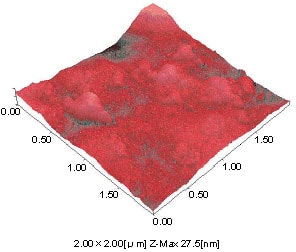

Fig.4 Printed Part of Red Ink

The picture below shows a surface image of printed part.

Fig.4 shows part painted with red, and fig.5, 3D image of an area painted blue. The data are painted with pseudo colors, which has provided very persuasive images.

Fig.5 Printed Part of Blue Ink