SPM Observation of Thin-Film Cross-Sections

Introduction

Observing the shape of thin-film cross sections is arguably of more interest than observing the surface. One of the primary objectives is to measure the film thickness. It is also used to observe the boundary between the film and the substrate, the boundaries between multiple thin-film layers, and the graininess within the layers. Cross-sectional observation can also be described as an important observation technique with regard to investigating adhesion and diffusivity between thin films of different types. Until now, however, SPMs (which use microscopic probes) have hardly ever been used for the observation of cross sections and edges because the probe would break or control around the edges would be difficult. Here we present an example, together with data, showing that cross-sectional observation of thin films is possible using an SPM. A description of the wide range of know-how that is required to perform cross-sectional observation, from sampling to measurement, is also provided. We used a specimen consisting of silicon-oxide film and organic film formed on a silicon substrate and a specimen consisting of an ITO film (transparent conductive film) formed on a glass substrate using crystal growth.

SPM observation of a Si-oxide layer cross-section

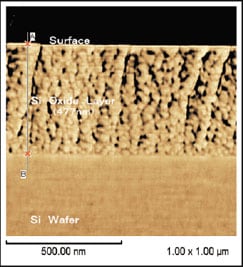

Fig. 1 shows a COS image obtained for a cross section of the silicon-oxide layer. The thickness was measured at 477 nm. The graininess within the oxide layer and the appearance of the boundary with the substrate can be observed.

In general, SPM observation of cross sections (including those within surfaces) is regarded as unfeasible because the scan can become unstable when the probe becomes separated from the surface, and there are cases where the probe breaks. Therefore, in order to facilitate cross-sectional observation using SPM, the amount by which the tip of the probe is displaced from the edge of the specimen must be minimized, and a device with a level of operability sufficient to facilitate accurate positioning of the observation field of view is required.

The simplest way of obtaining a cross section of the specimen is to break the silicon wafer in a natural way. No form of pretreatment, such as polishing, is required. Before setting the specimen in the SPM, the cross section is observed with an optical microscope, and a place where the specimen has broken into a relatively flat way is marked.

Fig.1 Cross section of a thin Si-oxide layer on a Si-wafer

In Fig. 1, the oxide layer is shown on top. In actual measurement, however, the cantilever scanning direction is at right angles to the layer. Measurement was performed in dynamic (vibration) mode but contact mode would have been acceptable. Phase images and COS images represent the surface topography well and are suitable for cross-sectional observation.

SPM observation of an organic thin-film cross-section

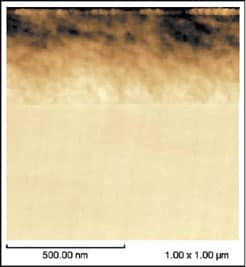

Fig.2 Cross section of an organic thin film (Topographic image)

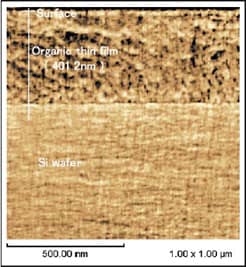

The cross section of a specimen consisting of organic thin film deposited on a silicon wafer was observed to obtain topographic and COS images. These images are shown in Fig. 2 and 3. The surface is at the top of each image. The film thickness was measured at 401.2 nm.

Fig.3 Cross section of an organic thin film (COS image)

Boundary observation between an ITO thin film and glass

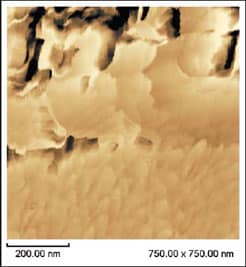

Fig.4 Boundary observation between an ITO thin film and glass (Phase image)

Fig. 4 shows a phase image obtained for the boundary between ITO film and glass. The top part of the image is a cross section of the ITO film. The cross section was obtained by cutting from the glass side with a cutter. No form of pretreatment, such as polishing, was performed. In this image, which is 100,000 times the actual size, the part where the ITO film is joined to the glass can be seen clearly.

The phase image offers a higher resolution than the topographic image. It also includes information about the physical properties of the surface, such as viscoelasticity, and is therefore a valuable form of observation.

SPMs are also used to make cross-sectional observations and to evaluate the quality of ITO film, which varies with the deposition conditions.