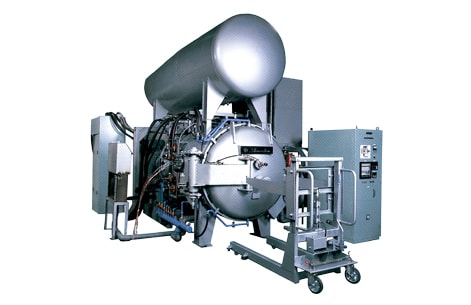

Features

- Gas Pressure Cooling

Gas pressure can be increased up to 0.5 MPa·G during cooling. This allows for easy quenching of large pieces of die steel and high-speed steel. - Distortion-Free

During cooling, cooling gas is sprayed into the furnace chamber from above and below to provide uniform cooling. This results in extremely low levels of distortion.

Applications

- Heat Treatment of Metals

Vacuum Quenching

Vacuum Tempering

Vacuum Annealing

Precipitation Treatment

Solution Treatment

PHG Series Specifications

| Vacuum Quenching Furnace | ||

|---|---|---|

| Model | PHGgr40/40/60 | PHGgr60/60/60 |

| Effective Intern. Dim. (mm) W x H x D |

400×400×600 | 600×600×600 |

| Max. Temp. (°C) | 1350 | |

| Process. Cap. (kg gross) | 120 | 300 |

| Ultimate Press. (Pa) | 7×10-1 (7×10-3) |

|

| N2Gas Consumption (m3/cycle) | 120 | 200 |

| Water Coolant Capacity(m3/h) | 8 | 12 |