December 14, 2021 | News & Notices

Release of Gear Pumps with a Low-Noise Design, Supporting the Need for a Switch to Electric Motors

Adopted by Major Manufacturers of Forklifts in Europe

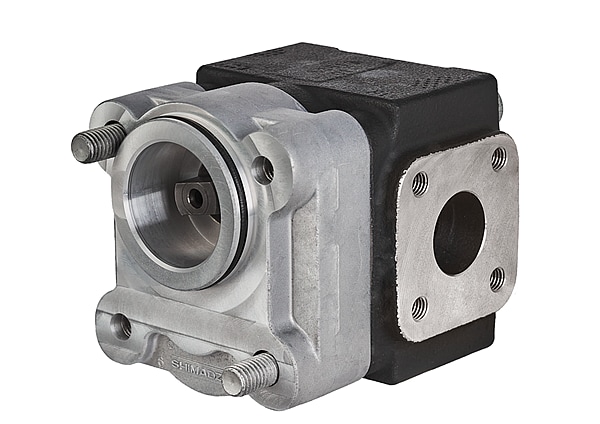

Shimadzu Corporation has released the newly developed Serenade SRP 300 series of gear pumps (hereinafter “gear pumps”). These gear pumps feature a low-noise design that reduces noise by up to 30 % in comparison to previous models. In a variety of fields, measures to reduce carbon dioxide emissions are progressing, and there is a strong push in the field of industrial vehicles such as forklifts, as well as in the construction machinery field to switch the drive source from combustion engines to electric motors. For the last 4 years, Shimadzu has been involved in developing these gear pumps to support the need for low-noise hydraulic equipment by switching to electric motors as the drive source. Two years ago, prototypes of these gear pumps were delivered to major forklift manufacturers in Europe, where environmental regulations are strict. The quietness of the pumps was highly regarded, and they have now been moved into mass production.

Gear pumps are a kind of hydraulic pump used to deliver hydraulic fluid when activating loading platforms on forklifts and other industrial vehicles. One forklift is equipped with 1 or 2 gear pumps. The demand for industrial vehicles is increasing year by year against a backdrop of increased volume of distributed goods in accordance with the expansion of the e-commerce market. In the midst of this, exhaust control regulations have been strengthened as an environmental countermeasure, and initiatives are being taken to achieve carbon neutrality. As a result, the percentage of forklifts with electric motors is increasing yearly, and it is expected that almost all will be motorized in future. Motorized forklifts are quieter than forklifts with conventional combustion engine drive systems. Accordingly, noise from the frame caused by gear pump drive noise and discharge pressure pulsations* is even more conspicuous. In order to reduce the noise stress on operators or other people, even quieter gear pumps are needed.

- * Vibrations occurring due to fluctuations in the flowrate of hydraulic fluid discharged by the gear pump.

Against this background, Shimadzu has developed and manufactured gear pumps using Serenade, our proprietary noise-reduction technology. Serenade technology is a manufacturing control technique for minimizing the gap (backlash) between the gears in the gear pump, one of the causes of discharge pressure pulsations. In this way, flowrate fluctuations are suppressed, reducing noise.

A feature of these gear pumps is that they were developed based on the sound quality evaluation index known as “loudness,” with the aim of further reducing noise. “Loudness” is an evaluative index focused more on human auditory sensation itself in comparison to “sound pressure level,” which is generally used for noise evaluations. By establishing noise-reduction techniques using “loudness,” Shimadzu has reduced the “loudness” value at the operator’s ear position by up to 30 % in comparison to previous models.

In future, the adoption of electric engines as a replacement for combustion engines as the drive source in industrial vehicles, construction machinery, agricultural machinery, and special-purpose vehicles will further accelerate, with the aim of resolving environmental issues. It is expected that this will produce a demand for quieter hydraulic equipment via conversion to electric motors as the drive source. Shimadzu will continue to develop a series of gear pumps with a low-noise design, aiming for their adoption not only in forklifts but also in construction machinery and other fields.

For more details, visit

Serenade