May 31, 2022 | News & Notices

Monitor Testing Machines from Anywhere at Any Time

Release of TRAPEZIUM SATELLITE Testing Machine Remote Monitoring System

Shimadzu announces the release of TRAPEZIUM SATELLITE, a remote monitoring system for testing machines. This system, which consists of a monitoring device, a USB camera, and software, is for remotely monitoring the operating status of fatigue testing machines using a web browser. The operating status of equipment can be checked while away from the laboratory, which heightens the efficiency of testing work and reduces workloads. If a problem with a test occurs, it can be discovered immediately, and previous image data can be checked retrospectively, enabling more reliable test results.

Fatigue testing machines are used in research and development and quality assurance departments in the iron and steel, chemical, and transportation equipment industries to check the strength and durability of new materials and components. In general fatigue tests, strength is investigated by applying a load repeatedly from 100,000 to 10 million times. Because fatigue testing machines produce vibrations and operating noise, they are typically situated in laboratories away from offices. In addition, since a single test usually takes between several days and two weeks, once the test has started, users will spend a lot of time away from the laboratory. As a result, multiple time-consuming trips to the laboratory to assess the test status will be required. More importantly, it can take several days to learn that a problem has occurred, which makes it difficult to check what happened.

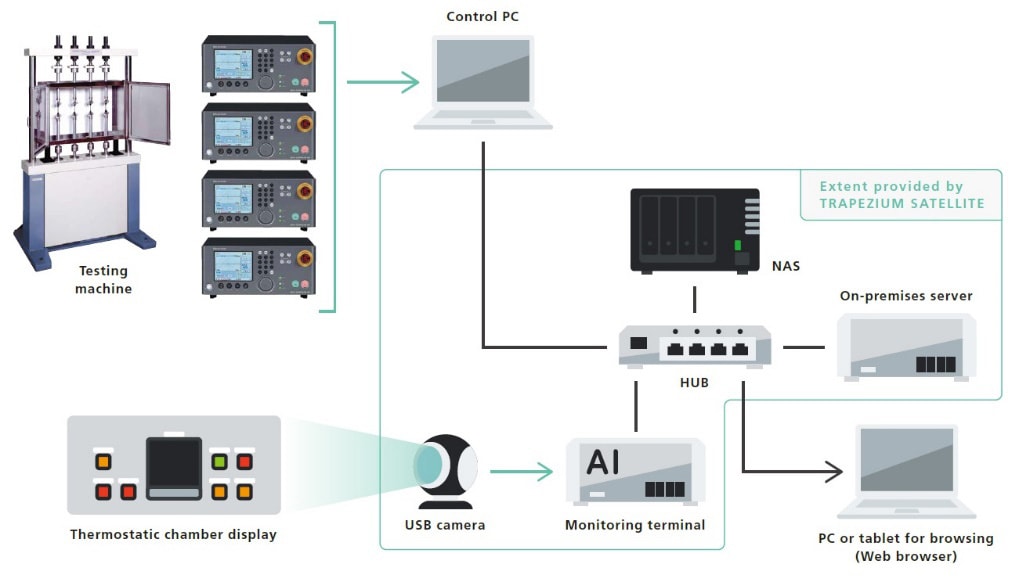

Typical Configuration of the TRAPEZIUM SATELLITE System

(When the optional monitoring device equipped with AI functionality is added to the on-premises edition)

This system enables the remote assessment of test conditions by checking instrument images using a USB camera and operating status data obtained from the fatigue testing machine. The camera images can be saved as a time series, and email notifications can be sent in the event of a problem. Normal operating status can be quickly restored by checking the test status retrospectively. In addition, AI analysis of images from the USB camera can be used to read numerical indicators and determine whether indicator lights are ON or OFF, so the test status of older fatigue testing machines and accessory equipment can be monitored. Since the instruments being monitored are listed in the software, their status can be seen at a glance.

With this system, Shimadzu is heightening testing efficiency and reducing the workload associated with fatigue testing machines, thereby contributing to higher quality testing work. This product supports the development of new materials and technologies from the standpoint of testing work.

Features

1. A Variety of Data from Within the Laboratory Can be Acquired Remotely

Up to 180 cameras can be connected, so users can get an overall view of multiple instruments and accessories as well as the status of samples being tested. Data indicating operating status can be acquired directly from fatigue testing machine controllers, enabling the real-time assessment of numerical values as well as fluctuations. Videos of instruments are automatically saved if the status changes, so the testing situation can be reviewed. The latest test results and USB camera videos can be downloaded and checked on a computer from anywhere at any time.*1

- *1 The content that can be inspected depends on the network environment at the installation site.

2. Assess the Operating Status of Any Instrument Using AI Monitoring Functionality

Using optional AI monitoring devices and AI cameras, operating status can be digitized through AI image analysis of indicator lights and numerical indicators in camera images. The operating status of older model instruments and other brands of instruments can also be assessed.

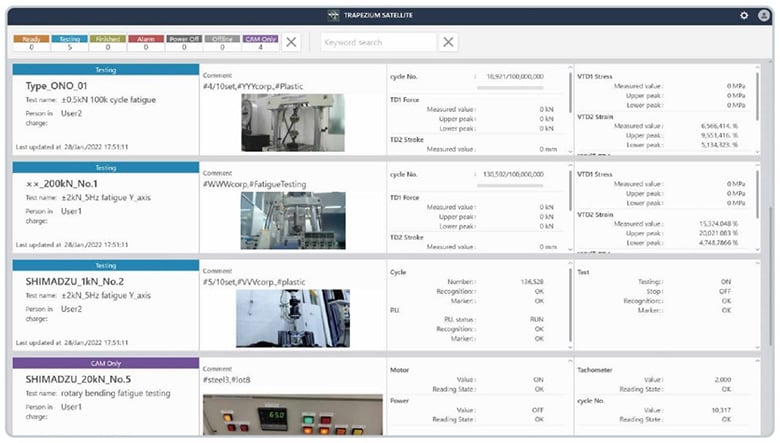

3. Lists of Operating Status for Multiple Instruments

The status of all instruments can be displayed together, allowing users to understand the status of the laboratory at a glance, without standing in front of each instrument. In addition, it is possible to specify an interval and download the corresponding operating logs. Availability factor calculations can easily be performed by tabulating the operating status separately.

- Note: The details noted in this press release describe the functionality of a system configured with optionally available items.

Product Photo: TRAPEZIUM SATELLITE Software Window

For more details, visit

TRAPEZIUM SATELLITE