February 22, 2021 | News & Notices

Shimadzu Introduces SPM-Nanoa Scanning Probe Microscope

Provides High-Level Operability and High-Speed Processing, with Automated Optical Adjustments and Observation Conditions Settings

SPM-Nanoa (main unit only)

Shimadzu has released the SPM-Nanoa scanning probe microscope. This high-sensitivity instrument provides high-resolution observations, features a low-noise detection optical mechanism, and automates optical adjustments and the work of setting the observation conditions. It will contribute to the evaluation of, and research into, cutting-edge nano materials as a mid-range scanning probe microscope (SPM).

In a scanning probe microscope, a probe with a tip on the order of 10 nm in size is brought close to a sample. A scan is performed while detecting the strength of the mechanical and electromagnetic interactions between the sample and the probe, thereby obtaining information on the three-dimensional shape of the sample surface and its physical characteristics. With an electron microscope, which uses an electron beam, observations must be performed in a vacuum, but an SPM can be used in air or in a liquid.

A scanning probe microscope can be used to observe the shape and evaluate the physical characteristics of high polymer materials, battery materials, and nano materials, and can address a variety of issues with respect to nanotechnology and nanoscience. With conventional instruments, however, experience and specialized knowledge are required to make optical adjustments and set the observation conditions. These procedures have been automated in the SPM-Nanoa, so even users unfamiliar with the operating procedures can easily acquire high-resolution observation data.

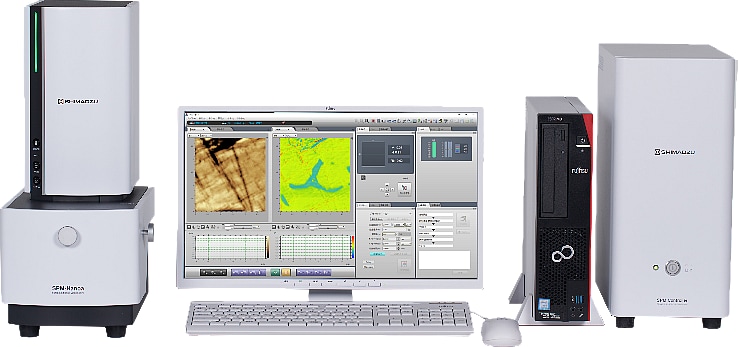

SPM-Nanoa (with controller and computer)

Features

1. High-Resolution Observations Obtained Easily by Anyone

Optical adjustments and the setting of observation conditions in air and liquids have been automated. In the newly added Simple Mode, automation has been incorporated for all processes, from probe positioning to optical axis adjustments, sample positioning, setting of observation conditions via proprietary algorithms, and correction of the acquired images.

2. Optical Mechanisms Adopted from the High-End Model

High-sensitivity, low-noise signal detection has been provided by adopting detection optical mechanisms from the SPM-8100FM, our high-end model. As a result, smaller interaction forces can be detected, simplifying the observation of soft gel materials. Additionally, the complex response of the probe in liquid is accurately detected and controlled, and in-liquid observations have been automated. The instrument is compatible with images up to 8K in size (8192 × 8192 pixels), which ensures high resolution is maintained even during wide area observations. Additionally, the optical microscope and SPM mechanisms have been integrated, reducing the impact of vibrations, and enabling target searches via stable optical microscope observations.

3. Time to Acquire Data Reduced to 1/6th

By improving the above-mentioned optical mechanisms, the process from setting up the SPM observations to acquiring the data, which conventionally required about 30 minutes, is completed by the SPM-Nanoa in five minutes. Additionally, elastic modulus distribution measurements, which conventionally took at least four hours, are completed in approximately 20 minutes using the dedicated Nano 3D Mapping Fast optional software.

For more details, visit

SPM-Nanoa