July 1, 2022 | News & Notices

Detecting Flaws within Objects Quickly and Easily Using Ultrasonic and Laser Light

Release of the MIV-X Ultrasonic Optical Flaw Detector

Photo: MIV-X Ultrasonic Optical Flaw Detector

Shimadzu Corporation announces the release of the MIV-X ultrasonic optical flaw detector. This product visualizes and digitizes flaws (peeling, cracks, and voids) in parts and multi-materials in aircraft, automobiles, and electrical and electronic equipment using our proprietary ultrasonic optical flaw detection technology*, which acquires an image of the propagation of ultrasonic

on the surface of an object. While inheriting the basic performance of its predecessor, the MIV-500, which could inspect an area up to 400 mm by 600 mm in approximately 20 seconds, this product offers significant advancements contributing to the evolution of a highly functional nondestructive inspection system, including a noise removal function that enables even clearer imaging, a function to measure the size of flaws, and an increase in resolution from a minimum detection size of 1 mm to 0.5 mm. This complements the conventional process of checking for flaws with a hammering test, and also provides automatic logging of the measurement results.

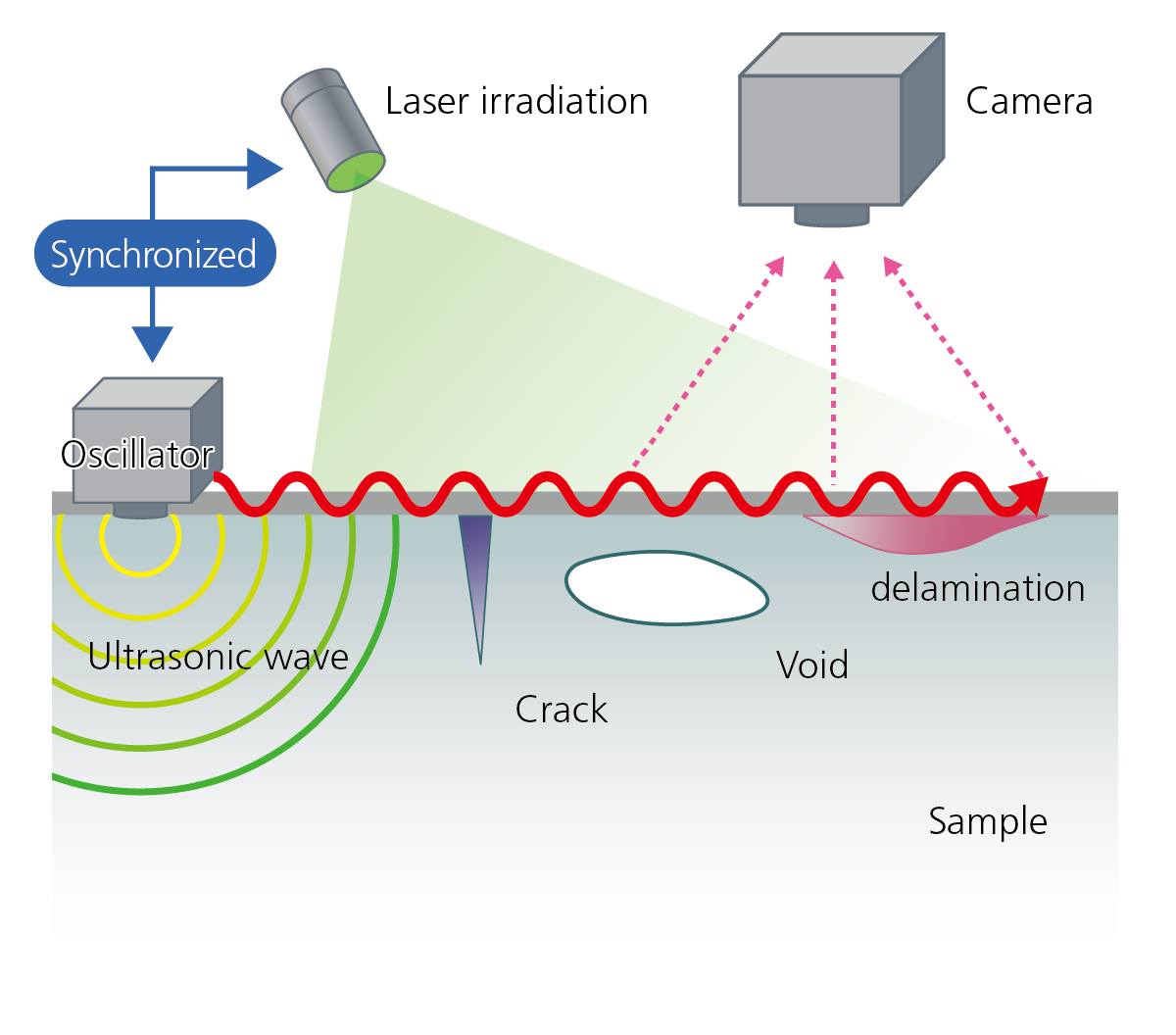

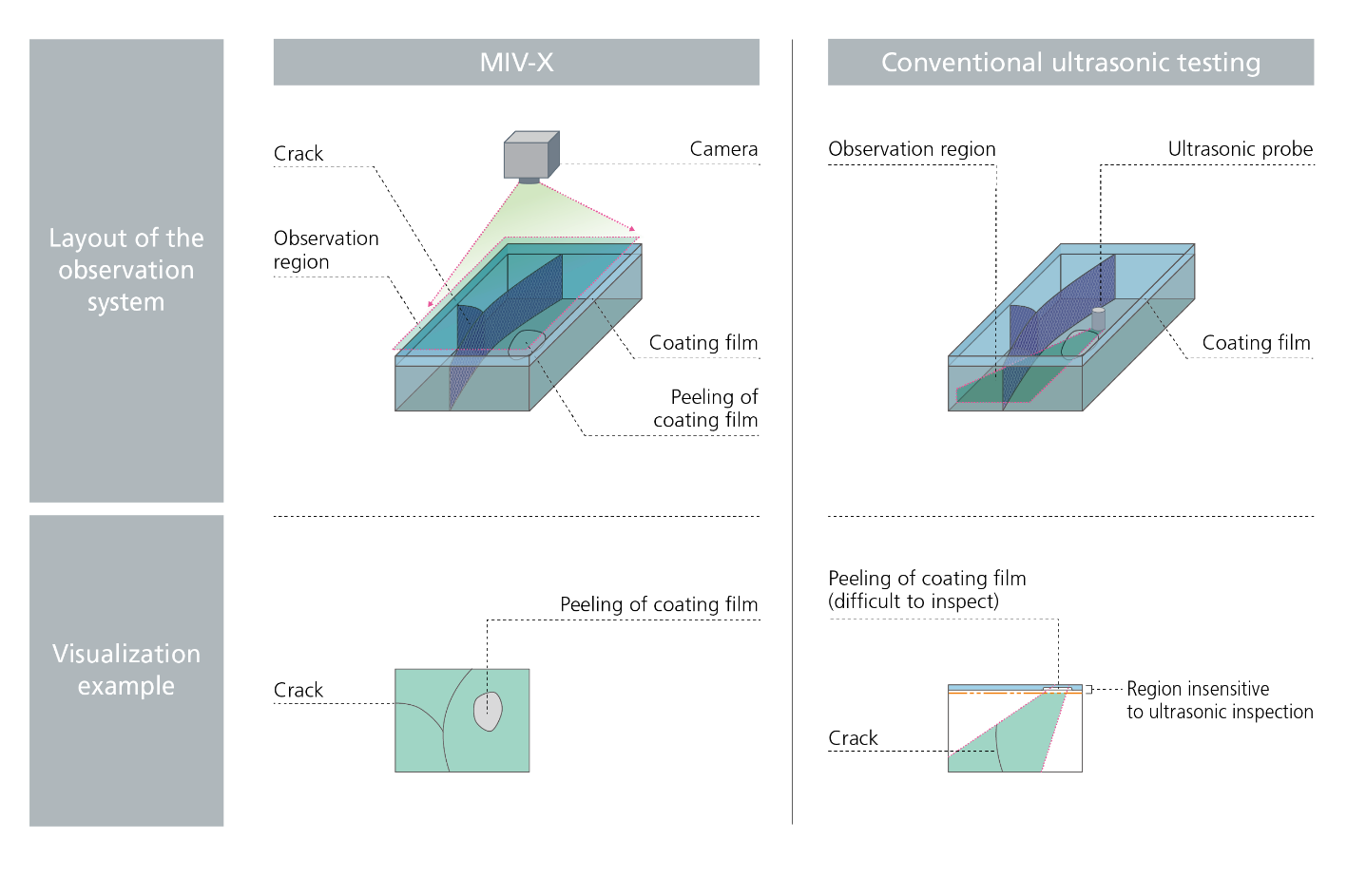

Ultrasonic optical flaw detection refers to nondestructive inspection technology that uses ultrasound and light. The surface of the test object is excited using ultrasound, and the tiny changes in the surface produced by these vibrations are detected using laser irradiation and a camera. If peeling, cracks, or other flaws are present, ultrasound discontinuities (propagation disturbances) are detected. Ultrasonic optical flaw detection enables the visualization of internal flaws (at a depth of about 1 mm) that are hard to find using conventional ultrasonic testing. It can easily detect flaws in joints and bonding surfaces in research and development processes involving multi-materials, which are created by combining different materials to increase strength and reduce weight. Shimadzu is marketing the MIV-X ultrasonic optical flaw detector to manufacturers and contract analysis companies of transportation equipment and machinery, raw materials, and construction, as well as research agencies engaged in the development of multi-materials and other new materials.

- *This technology is patented in Japan, China, and the United States.

Illustration: Principle behind Ultrasonic Optical Flaw Detection

Table: Comparison of Ultrasonic Optical Flaw Detection and Ultrasonic Testing

Features

1. Noise Removal Function Simplifies Flaw Identification

The instrument is equipped with a function to digitally remove noise in the window showing the propagation of the ultrasound, simplifying flaw identification.

2. Function to Measure and Mark the Size of Flaws Detected

The instrument is equipped with a user interface that simplifies operations, such as displaying a scale (ruler) on acquired images of cracks and peeling and measuring the distance between two selected points.

3. Optical Zoom Set Doubles Detection Capabilities

Attaching the provided zoom lens accessory to the camera unit approximately doubles the flaw detection resolution, from a minimum size of 1 mm to 0.5 mm.

For more details, visit

MIV-X