Background : What Can Affect Measurement Accuracy? - "Stray Light"

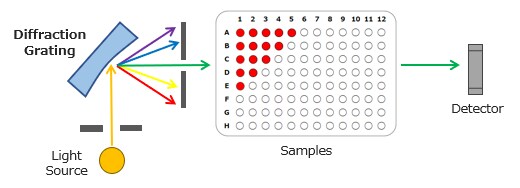

Monochromator-type microplate readers typically use diffraction gratings as their dispersive element. Since monochromator-type microplate readers require precise wavelength selection, stray light can significantly impact measurement accuracy. If the selected wavelength contains a lot of stray light, it acts as noise, leading to low measurement accuracy. To improve measurement accuracy, it is effective to select diffraction gratings with low stray light, in addition to designing the entire monochromator that suppresses stray light.

Structure of Microplate Readers

Advantages of Shimadzu products

★Advantage : Low Stray Light and High Diffraction Efficiency

Shimadzu diffraction gratings are produced by precisely replicating from the master gratings with extremely low stray light which are made by the holographic exposure method. Shimadzu is also the first company to establish the technology for manufacturing blazed holographic grooves, which ensure low stray light compared to conventional mechanically ruled gratings, while maintaining high diffraction efficiency. Shimadzu diffraction gratings are highly regarded for their low stray light, and have contributed to improving the measurement accuracy of many types of spectroscopic analyzers.

Shimadzu Diffraction Gratings suitable for Microplate Reader

Concave Blazed Holographic Gratings for Monochromators : M1198-XXX Series

Outline Specification of M1198-XXX Series

| Wavelength Range [nm] | Nominal Blaze Wavelength [nm] | Code Number |

|---|---|---|

| 190 ~ 800 * | 250 | M1198-03 |

| 200 ~ 800 * | 300 | M1198-01 |

| 350 ~ 850 * | 460 | M1198-02 |

*This grating has also been adopted for microplate reader application up to 1000nm.

・Groove density : 1198 [grooves/mm]

・Dimensions :42.4 (W) × 42.4 (H) [mm]

・Central thickness : 7.7 [mm]

*Contact us for the diffraction efficiency curve and the imaging characteristics.

(*Click to launch the email software)