High Measurement Precision Achieved with Low-Precision Ground Surface

Ever since the first KPR-1 model was released in 1972, Kalnew brand refractometers have maintained a strong reputation in the marketplace while expanding the product line to offer higher precision, digital technology, and automation.

Optical design refinements, assembly technology, and other expertise cultivated over many years have resulted in the highest precision ever offered by the KPR.

The V-block design enables even more convenient high-precision measurement.

This page may contain references to products that are not available in your country. Please contact us to check the availability of these products in your country.

Unique V-Block Type Refractometer Satisfies a Wide Range of Requirements

●V-Block Design Achieves High-Speed and High-Precision Measurements

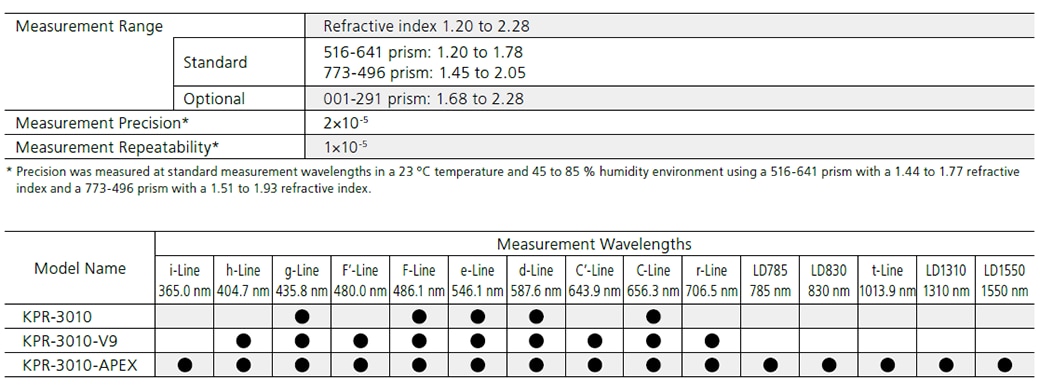

With ±2 × 10-5 measurement precision, measurements can be obtained in about 14 seconds per wavelength. It also inhibits operator-dependent measurement errors in order to provide precise and consistent measurement results.

●Wavelength Dependence and Temperature Dependence Information can be Obtained

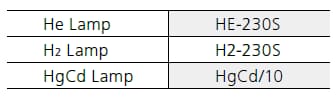

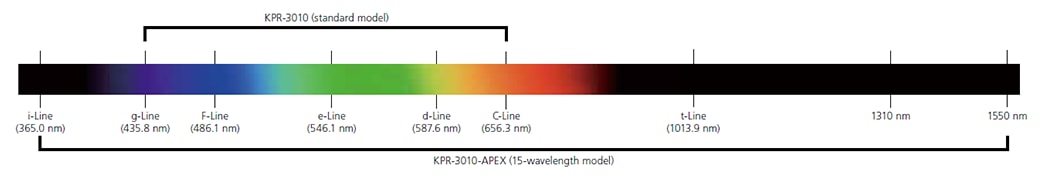

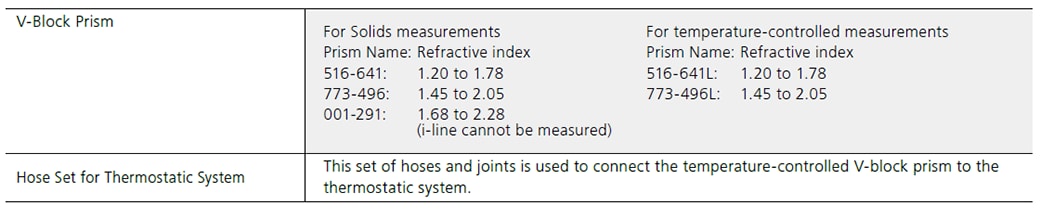

Three models are available, equipped with a light source capable of a standard 5 wavelengths or up to 15 wavelengths depending on the requirements of each application. If an optional temperature-controlled V-block prism is used, temperature dependence information can be obtained for a temperature range from 10 to 70 ℃.

V-Block

Each V-block prism is meticulously ground, adjusted, and joined one by one.

This key component satisfies the opposing requirements for both high precision and convenience, achieved to a high level.

●Suitable for Measuring a Wide Range of Samples, from Very Small Samples to Highly Volatile Liquids

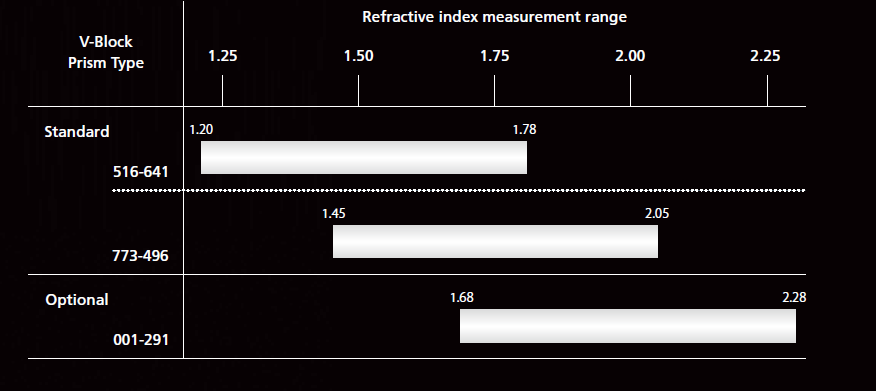

The refractometer can measure either solids (glass, plastics, etc.) or liquids. The ability to measure a broad range of refractive index levels from 1.20 to 2.28 means a wide range of samples can be measured. Because solid sample surfaces do not need to be polished to precise levels, it can significantly reduce the time and trouble involved in sample preparation compared to when using the minimum deviation method. Liquids can be measured using an optional temperature-controlled V-block prism.

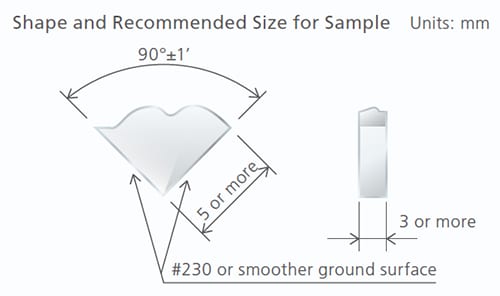

●Sample Size

The quality of sample preparation affects the precision level of refractive index measurements.

To obtain precise refractive index measurements, make sure the samples are prepared to the specifications indicated to the right.

Achieving a More User-Friendly and Convenient Operating Environment

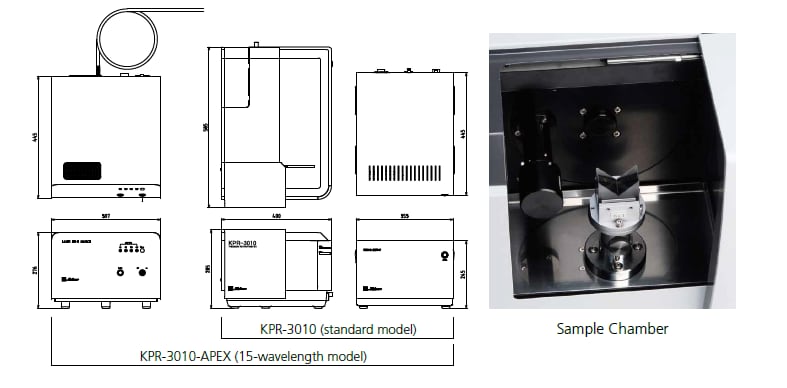

●Designed for Usability with a Spacious Sample Chamber and Simple Design

Locating the sample chamber on the front side makes it easy to attach and detach samples.

The 165 mm wide opening to the sample chamber makes it easy to insert and remove samples.

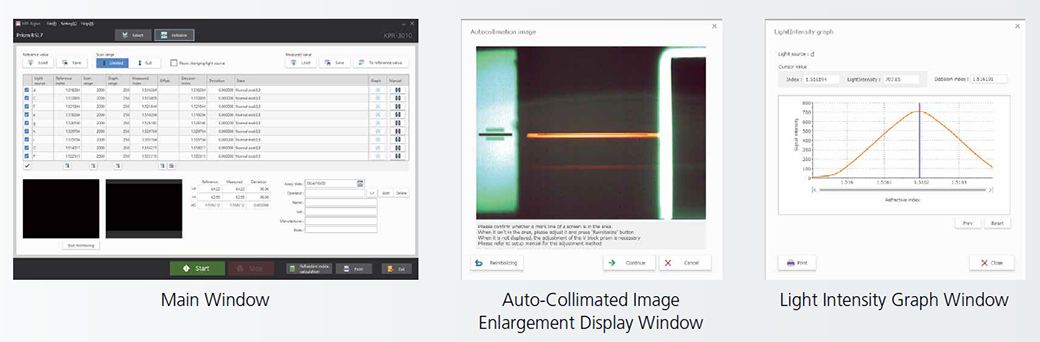

●Control Software Designed for Usability Accurate Determination of Sample Status by Displaying Slit Image

An auto-collimated image is displayed in the software to make adjustments easier during V-block replacement. In addition, because the slit image being measured is displayed together with the light intensity graph, it can be useful for discovering minor differences between samples and abnormalities not indicated by the refractive index. Furthermore, functionality was added for automatically calculating the refractive index of the D-line (589.3 nm). The D-line refractive index is calculated using dispersion equations based on results from measuring 3 standard wavelengths at the d-line, C-line, and F-line. By using an optimal combination of measurement wavelengths and dispersion equations, the results obtained are equivalent to results obtained calculating the refractive index of the D-line based on the refractive index values at sodium lamp brightline wavelengths D1 (589.6 nm) and D2 (589.0 nm).

Specifications

Optional Accessories and Related Products

Consumables