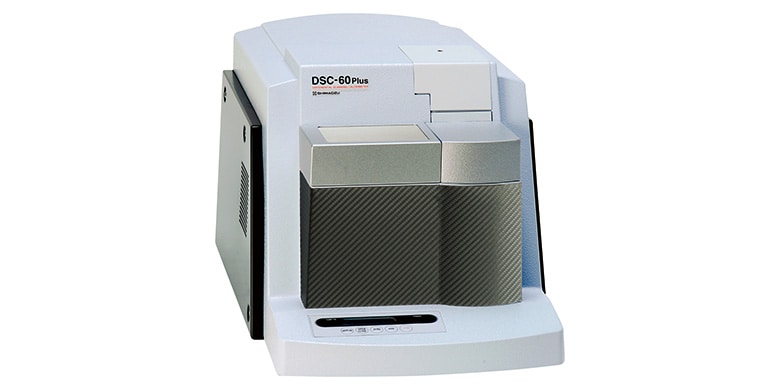

DSC-60 Plus Series

The physical properties of plastics are greatly affected by their thermal history, including the temperature and cooling conditions during molding and the recycling and use environment temperatures of the material. Thermal history refers to the history of temperature changes which a material undergoes. Control of the thermal history of plastic products is extremely important for eliminating product defects and stabilizing product quality. When a defect occurs in a product, a knowledge of the heat environment to which the product was exposed provides useful information for improving defects. It is possible to investigate whether a product was exposed to this type of thermal history or not by using a differential scanning calorimeter (DSC). In crystalline polymers, there are cases in which an endothermic peak appears near the heat treatment temperature of a sample on the low temperature side from the main endothermic peak caused by melting. However, this type of melting peak is difficult to discover in a DSC curve if it appears as a small inflection point, and not as an endothermic peak. In such cases, it has been reported that a derivative DSC curve is effective. This article introduces an example in which the relationship between the heat treatment temperature and heat treatment time of high density polyethylene was obtained by a technique for estimating the heat treatment temperature and heat treatment time from the on-set temperature and peak top temperature of a derivative DSC curve of an endothermic peak which appeared as a result of heat treatment.

November 20, 2020 GMT

Some products may be updated to newer models