Measures and Proposals to Reduce Helium Gas Consumption (GC)

- Measures and Proposals to Reduce Helium Gas Consumption

- Reducing Consumption During or After Analysis

- Shutting off the Gas Supply After Analysis

- Changing the Carrier Gas

There is an increased focus on lowering running costs and reducing the burden on the environment. Helium gas (He) is a precious resource and must be used carefully by consuming as little of it as possible. Here, we introduce functions to reduce the rate of helium gas consumption and describe important precautions when switching to another carrier gas.

Reducing Helium Consumption

Describes methods for reducing helium gas

consumption during or after analysis.

Application

Movies

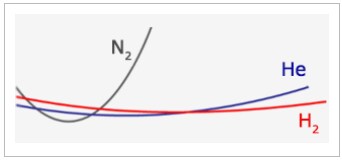

Converting GC Methods from Helium to Hydrogen