Tensile Tests of Films

Standard No. ISO527-3: 2012 (JIS K 7127: 1999)

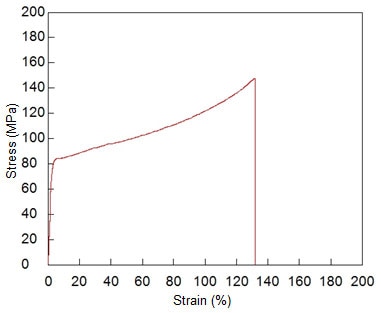

Tensile tests are widely used to evaluate plastic materials, and the results are used as indices for new materials development and for implementing quality control. Items widely evaluated as tensile characteristics of plastic materials include the tensile modulus, strength, and break strain. Here, break strain was measured based on displacement data acquired using an extensometer. The strength was also evaluated.

Measurements and Jigs

Non-contact type extensometers capable of displacement measurements without affecting the sample properties are effective for accurately measuring the break strain of a film. In measuring such physical properties, the sample must be gripped evenly,suppressing the occurrence of wrinkles, so it is important to choose the grips carefully. As in this test, the use of a non-contact type extensometer/width sensor and foil grips is recommended for film tensile tests.

| Tester | AGS-X |

| Load Cell | 1 kN |

| Test Jig | 1 kN grips for foils |

| Extensometer | TRViewX 240S non-contact extensometer/width sensor |

| Software | TRAPEZIUM LITE X |

- A high-precision load cell is adopted. (The high-precision type is class 0.5; the standard-precision type is class 1.)

Accuracy is guaranteed over a wide range, from 1/500 to 1/1 of the load cell capacity. This supports highly reliable test evaluations. - Crosshead speed range

Tests can be performed over a wide range from 0.001 mm/min to 1,000 mm/min. - High-speed sampling

High-speed sampling, as fast as 1 msec. - TRAPEZIUM LITE X operational software

Designed for intuitive operation, this software offers excellent convenience and user friendliness. - Jog controller (optional) This allows hand-held control of the crosshead position. Fine position adjustment is possible using the jog dial.

- Optional Test Devices

A variety of tests can be conducted by switching between an abundance of jigs in the lineup.