Tensile Tests of Plastic Materials at Low Temperatures (-40 °C)

Tensile Tests of Plastic Materials at Low Temperatures (-40 °C) 【Standard No. ISO527-1: 2012 (JIS K 7161: 1994)】

Introduction

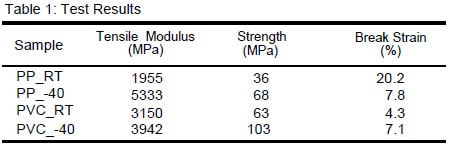

Tensile tests are widely used to evaluate plastic materials, and the results are used as indices for new materials development and for implementing quality control. Items evaluated as tensile characteristics of plastic materials include the tensile modulus, strength, and break strain. In this Data Sheet, the tensile modulus of polypropylene (PP) and polyvinyl chloride (PVC) specimens (dumbbell shaped and cut types) was calculated based on displacement data acquired using an extensometer at a low temperature of -40 °C. In addition, the strength and break strain for the respective plastic materials were also evaluated.

Measurements and Jigs

In finding a sample's tensile modulus, it is necessary to use an extensometer capable of measuring tiny deformations of the sample with high accuracy. Measurements of crosshead travel distances include errors not only from sample deformation, but also from load cell and test jig deformation. When the deformation region is very small, the ratio of the error becomes significant, so this data is not suitable for tensile modulus calculations. In such cases, an extensometer that can measure changes in the gauge length with an accuracy of at least ±1 % must be used. When measuring the modulus of elasticity with a 50 mm gauge length, this corresponds to an accuracy of ±1μm. In this test, a one-touch contact type extensometer, capable of operating even in a -40 °C environment, was used.

Measurement Results

In the results, samples with an "RT" suffix were measured in a room temperature environment, and those with a "-40" suffix were measured at -40 °C. In all cases, measurement was performed at a test speed of 1 mm/min up to 2 %, and then at a test speed of 50 mm/min. In the room temperature measurements, the extensometer measurement range was exceeded, so the extensometer was removed at the 2 % position.

Plastic Material Thermostatic Tensile Test System

| Tester: | AGS-X |

| Load Cell: | 5 kN |

| Test Jig: | 5 kN pneumatic flat grips (single-side file teeth grip faces) |

| Extensometer: | Strain gauge type one-touch extensometerEPC-50-10 |

| External Amplifier: | ESA-CU200 |

| Thermostatic Chamber: | TCR2W |

| Software: | TRAPEZIUM LITE X |

- A high-precision load cell is adopted. (The high-precision type is class 0.5; the standard-precision type is class 1.)

Accuracy is guaranteed over a wide range, from 1/500 to 1/1 of the load cell capacity. This supports highly reliable test evaluations. - Crosshead speed range

Tests can be performed over a wide range from 0.001 mm/min to 1,000 mm/min. - High-speed sampling

High-speed sampling, as fast as 1 msec. - TRAPEZIUMX LITE X operational software

This is simple, highly effective software. - Jog controller (optional)

This allows hand-held control of the crosshead position. Fine position adjustment is possible using the jog dial. - Optional Test Devices

A variety of tests can be conducted by switching between an abundance of jigs in the lineup.