Aluminum Alloy Analysis

Aluminum Alloy Analysis

Due to dramatic advances in science and technology in recent years, all kinds of products have become smaller and lighter.

Aluminum is well known for its lightness but it also offers the properties of excellent thermal and electrical conductivity and good ductility.

Due to the poor physical strength of pure aluminum, aluminum alloys that have appropriate elements added and are heat-treated to dramatically improve their strength are widely used in various products. Microstructural analysis is indispensable to control the mechanical properties, lightness, corrosion-resistance, water resistance, and machinability of these aluminum alloys. This Application News introduces the analysis of aluminum alloys by EPMA.

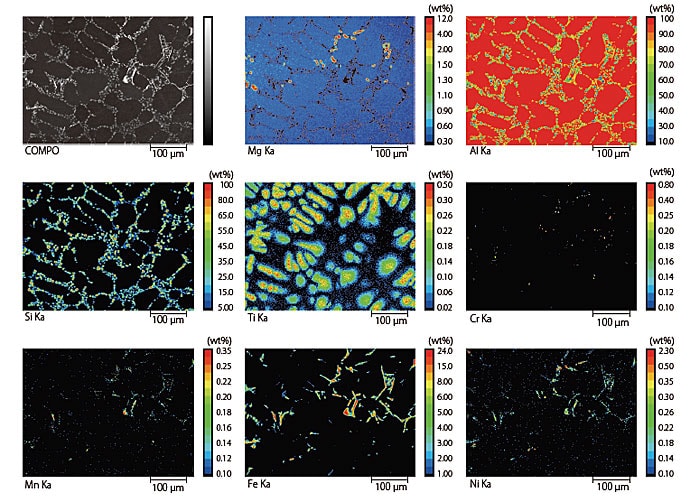

AC4CH (Al-Si-Mg(Fe)) aluminum foundry alloy is widely used for automobile cast components that offer excellent mechanical strength. During the manufacture of AC4CH, spheroidization of eutectic Si particles occurs and banded structures of Mg or Fe-containing intermetallic compounds are formed at areas of eutectic melting. In Fig. 1, the spheroidal eutectic Si is distributed in bands that partially match those at approximately 0.3 % Mg content .

It is apparent that coarse intermetallic compounds, such as the 0.2 % max. Fe additive element, exist at areas of eutectic melting.

Fig. 1 AC4CH Mapping Images

EPMA-1720 Series Electron Probe Microanalyzers

The electron probe microanalyzer is a non-destructive measurement instrument that irradiates the sample with a finely focused electron beam to reveal the element composition of small areas. It allows the highly sensitive analysis of elements in micron-scale regions on the sample. Simultaneously using submicron-order quantitative analysis and SEM images permits applications to shape inspections. Cause analysis can be performed immediately after foreign matter is discovered.