Measurement of Residual Solvents in Pharmaceuticals by Headspace GC - USP <467> Residual Solvents Procedure A-

Residual solvents in pharmaceuticals are defined as volatile organic compounds used in or generated from the manufacture of drug substances, pharmaceutical additives, or drug products. They are strictly controlled according to risk classifications from Class 1 to Class 3, which are based on the risk to human health.

Headspace GC methods specified in the USP (U.S. Pharmacopeia), General Chapters <467> Residual Solvents, are commonly used for analysis of residual solvents. These USP methods were created based on the analytical methods specified in the EP (European Pharmacopoeia), in accordance with policies specified by the ICH (International Conference on Harmonisation of Technical Requirements for Registration of Pharmaceuticals for Human Use).

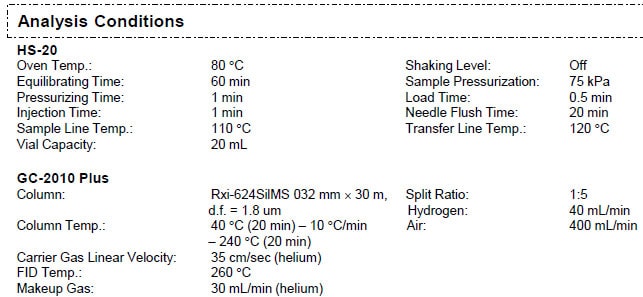

This time, we presents data obtained using the Shimadzu HS-20 Headspace Sampler and Shimadzu GC-2010 Plus Gas Chromatograph, from Class 1 and Class 2 standard solutions, in accordance with Water-Soluble Articles, Procedure A, in USP <467> Residual Solvents.

Results

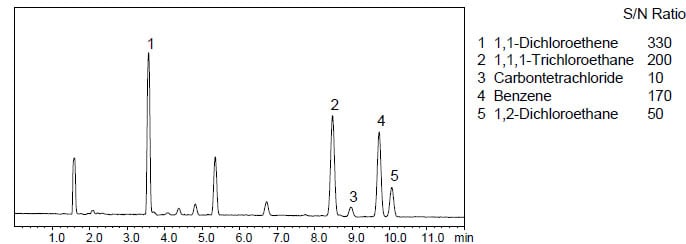

1. Class 1

Figure 1 shows the Class 1 standard solution chromatogram. Procedure A requires that the S/N ratio obtained for 1,1,1-Trichloroethane in this chromatogram be 5 or higher. As shown, the S/N ratio was 200. Even for carbon tetrachloride, which had the lowest sensitivity level, the S/N was 10.

Fig. 1: Water-Soluble Articles, Procedure A, Class 1 Standard Solution Chromatogram

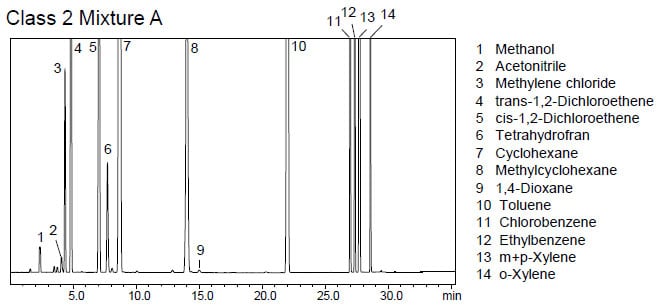

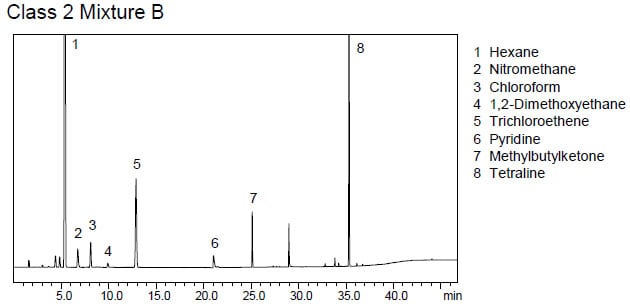

2. Class 2

Due to the large number of components in the Class 2 standard solution, it was separated into two mixtures: A and B. Respective measurement results are shown in Figures 2 and 3.

Fig. 2: Water-Soluble Articles, Procedure A, Class 2 Mixture A Standard Solution Chromatogram

Fig. 3: Water-Soluble Articles, Procedure A, Class 2 Mixture B Standard Solution Chromatogram

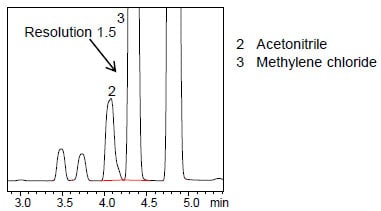

Fig.4: Separation Between Acetonitrile and Methylene Chloride

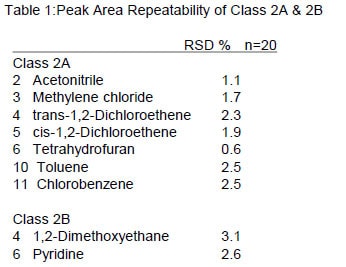

The area repeatability (RSD %) was evaluated by measuring the sample 20 consecutive times.

The resulting RSD % value was between 1 % and 3 %, which indicates a higher repeatability than obtained using previous headspace samplers (see Table 1).

The HS-20 headspace sampler achieves this unprecedented high repeatability by maintaining a uniform temperature distribution within the air tank oven and by using an advanced pressure control (APC) system for precise pressure control.

A Revolutionary System Aimed at Performance and Ease of Use

The HS-20 Series is the optimal solution for volatile component analysis. Its superior performance and user-friendly design support all types of analyses, from research to quality control.