TOC-L Series - Features

Total Organic Carbon Analyzer

680°C Combustion Catalytic Oxidation Method

Developed by Shimadzu, the 680°C combustion catalytic oxidation method is now used worldwide. One of its most important features is the capacity to efficiently oxidize hard-to-decompose organic compounds, including insoluble and macromolecular organic compounds.

TOC (total organic carbon) Measurement

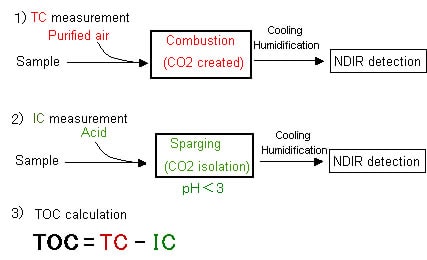

The 680°C combustion catalytic oxidation method achieves total combustion of samples by heating them to 680°C in an oxygen-rich environment inside TC combustion tubes filled with a platinum catalyst. Since this utilizes the simple principle of oxidation through heating and combustion, pretreatment and post-treatment using oxidizing agents are unnecessary, which enhances operability. The carbon dioxide generated by oxidation is detected using an infrared gas analyzer (NDIR). By adopting a newly-designed, high-sensitivity NDIR, the TOC-L series achieves high detection sensitivity, with a detection limit of 4μg/L, the highest level for the combustion catalytic oxidation method. The figure below is a schematic diagram showing TOC measurement using the 680°C combustion catalytic oxidation method and the NDIR method.

The sample is delivered to the combustion furnace, which is supplied with purified air. There, it undergoes combustion through heating to 680°C with a platinum catalyst. It decomposes and is converted to carbon dioxide. The carbon dioxide generated is cooled and dehumidified, and then detected by the NDIR. The concentration of TC (total carbon) in the sample is obtained through comparison with a calibration curve formula. 1) Furthermore, by subjecting the oxidized sample to the sparging process, the IC (inorganic carbon) in the sample is converted to carbon dioxide, and the IC concentration is obtained by detecting this with the NDIR. 2) The TOC concentration is then calculated by subtracting the IC concentration from the obtained TC concentration. 3)

NPOC (non-purgeable organic carbon) Measurement

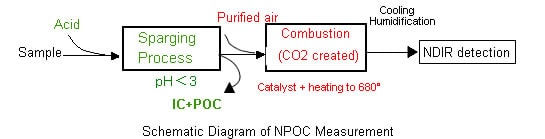

In environmental water and other samples in which the IC component of the TC is extremely large, significant errors may result if the abovementioned method is used for TOC measurement. Accordingly, the organic carbon in the sample is usually measured via an NPOC measurement as shown in the figure below. This method is the same as TOC measurement methods using acidification and sparging (IC removal) as described in official measurement methods (such as JIS and ASTM).

By sparging samples to which a small amount of acid has been added, the IC in the sample is converted to carbon dioxide. This carbon dioxide is removed, and the TOC is obtained by measuring the TC in the treated sample. When the carbon dioxide from the IC is removed, POC (purgeable organic carbon) may also be lost. Accordingly, the TOC obtained with this method may be referred to as NPOC. Shimadzu provides options that measure this POC, which is typically lost, enabling more complete TOC measurement.