LC/MS/MS Analysis of Vitamin D3 by the Co-Sense for Impurities System

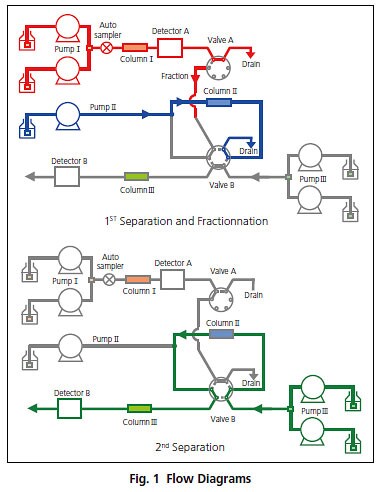

The Co-Sense for Impurities system offers analyte concentration and removal of impurities, and therefore comprises 3 flow lines: one for primary separation, another for concentration, and the third for secondary separation. Since a different mobile phase and column can be selected for each flow line, a combination of conditions can be used, including those that are conducive for separation at the primary separation stage and that are appropriate for detection for the secondary separation stage. Here we introduce an example in which Vitamin D3 capsules were analyzed by LC/MS/MS using such a method.

Analysis of Standard

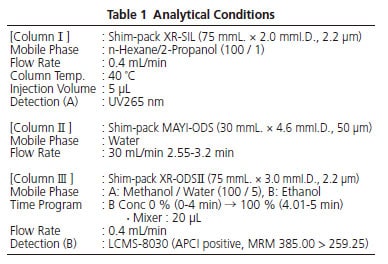

The Vitamin D3 sample was injected onto the Shimpack XR-SIL high-speed analytical column for normal phase analysis as the primary separation stage, and after being concentrated on the Shim-pack MAYI-ODS trap column, the sample was routed to the Shim-pack XR-ODS Ⅱ analytical column for reversed phase analysis as the secondary separation stage, after which it was detected by mass spectrometry. Table 1 shows the analytical conditions used for each of the processes.

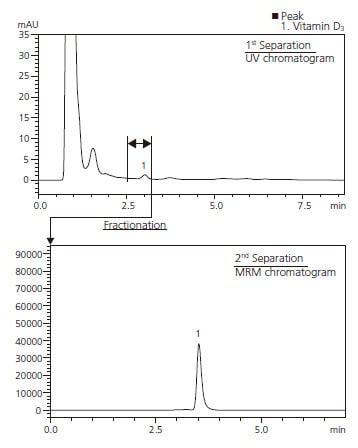

The chromatogram obtained during primary separation was monitored using UV detector (A), and was verified by the peak elution position of a standard. If analysis is started with that approximate peak time set in the Co-Sense for Impurities control software, valve A switches to send that fraction to be mixed with the flow from PumpⅡ so it is concentrated on trap column (Ⅱ).(upper diagram of Fig. 1)

After concentration for the time specified in the software, valve B is switched so PumpⅢ elutes the sample from the MAYI-ODS column and delivers it to column Ⅲ for the secondary separation stage and component detection by the mass spectrometer (Detector B).(lower diagram of Fig.1)

Although LC/MS is not suitable for detection during the normal phase primary separation, it provided good detection in the secondary separation on the reversed phase column. Excellent calibration curve linearity from 0.005 – 0.5 μg/mL was obtained, with a correlation coefficient R > 0.999. Furthermore, the peak area repeatability obtained using MRM chromatograms generated from 6 replicates of a standard solution (0.5 μg/mL) was 1.55 %RSD.

Result of Analysis

Fig. 2 Chromatograms of Oil-Soluble Vitamin Mixture Capsule

The liquid in the capsule that contained oil-soluble vitamins was dissolved in hexane.The entire process described above took approximately 9 minutes for a complete analysis cycle. The large amount of impurities present in the hexane are quickly eliminated during the primary separation, and only the Vitamin D3 and a small amount of impurities included in the normal phase fraction were selectively introduced into the secondary separation flow line.

Co-Sense for Impurities

Co-Sense for Impurities

The Co-Sense for Impurities system increases the sensitivity 10 to 20 times by performing online trap concentration of the impurity fractions obtained by 1-D separation, and subsequently performing 2-D separation. Compared to MS, it offers the advantages of (1) requiring no special analytical skill and (2) low initial capital costs to create the system, since an existing LC system can be expanded. The graphical user interface of the dedicated control software makes operation easy.