5-1) Heated Stirring (1)

Degassing Methods

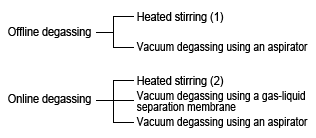

Up to the last section, we showed examples where degassing the mobile phase was required, but this section discusses the methods used for degassing. There are two basic methods of degassing, offline degassing and online degassing.

Offline degassing degasses the mobile phase in advance, before placing it at the pump inlet. However, the mobile phase starts redissolving air as soon as it is placed at the pump inlet, so there is little point in degassing it thoroughly. In contrast, in online degassing, degassing continues even during analysis. Its handling is a little time-consuming, but it is more effective in improving the reliability of analyses. Each method has its advantages and disadvantages, which are indicated below.

Heated Stirring (1)

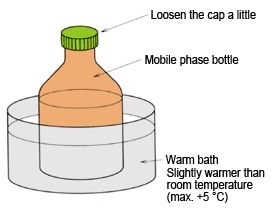

Fig. 19 Heated Stirring (1)

Heated stirring is used to reduce the dissolved air in the solution in the mobile phase bottle to the saturated solubility level. If cold solvent is being used from storage and if its temperature is expected to rise over a period from morning until noon, during analysis, or if water and acetonitrile are mixed then heating it a little will cause it to reach equilibrium more quickly. When the liquid temperature is low, the liquid density will differ (increase), which will also affect solvent delivery. Eliminating this effect is also one of the objectives of heated stirring.

Whether using an air-liquid separation membrane for online degassing or degassing by purging with helium, it is probably desirable to perform this process in advance.

Place the mobile phase bottle in a water bath slightly warmer than room temperature, with its cap loosened. Occasionally remove the bottle, secure the cap, and mix by shaking, then loosen the cap to release excess gases. This is exactly the same process as relieving the pressure of a separating funnel. The process is finished when the bottle is slightly warmer than room temperature. Wipe the walls of the bottle and place it at the pump inlet.

- The process is simple and requires no special equipment.

Disadvantages

- Degassing is only performed until the saturated solubility level is reached, so this cannot be used for low-pressure gradients or some other high-sensitivity detection methods.

- If overheated, excessive degassing can cause baseline drift as air is redissolved during analysis.

Applications

- Normal-sensitivity analysis using UV, refractometer, or fluorescence detection. However, back pressure must be applied to the detector if using a column oven, detector cell heating, or a high-pressure gradient. Note that it is preferable to keep the mobile phase bottle elevated or additionally use a bubble trap, as mentioned later in 5-6).