Visit user:

SARA Inc. (Okayama, Japan)

https://www.sarafarm.jp/en/

Abnormal weather events are becoming increasingly common throughout the world in recent years. Perhaps a natural disaster event involving heavy rain, strong winds, or other abnormal weather has occurred near where you live. Given the urgent need to deal with climate change problems, there is renewed interest in using woody biomass to help address forest and waste management challenges.

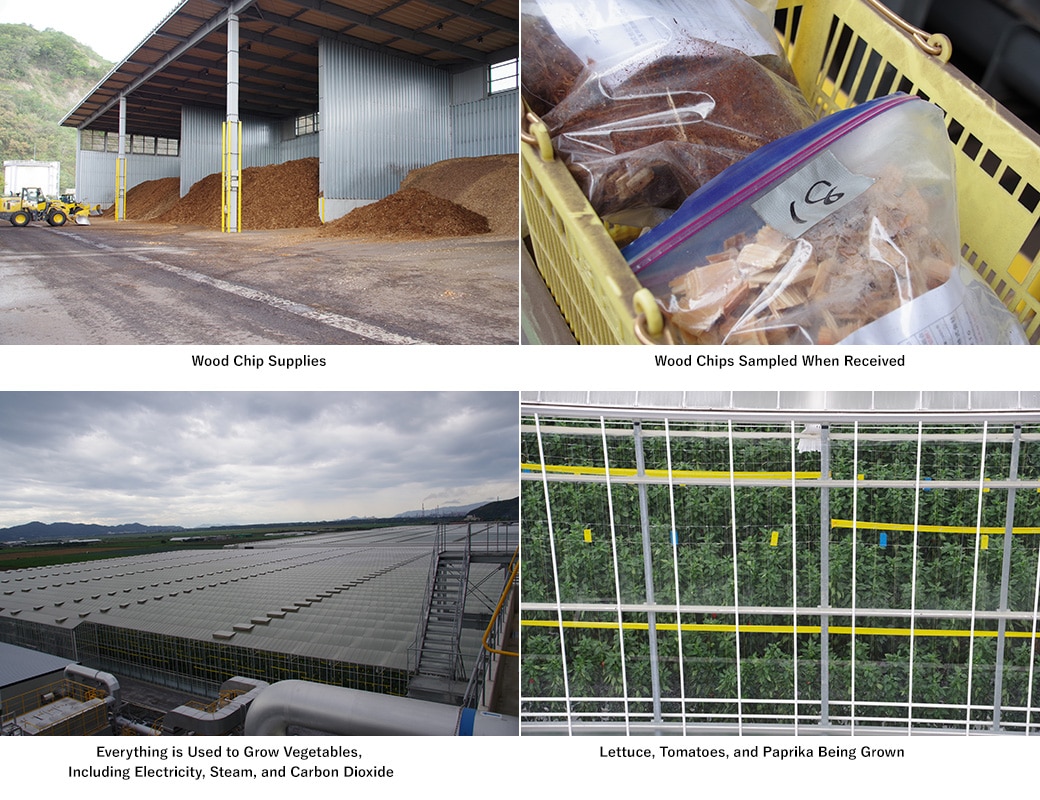

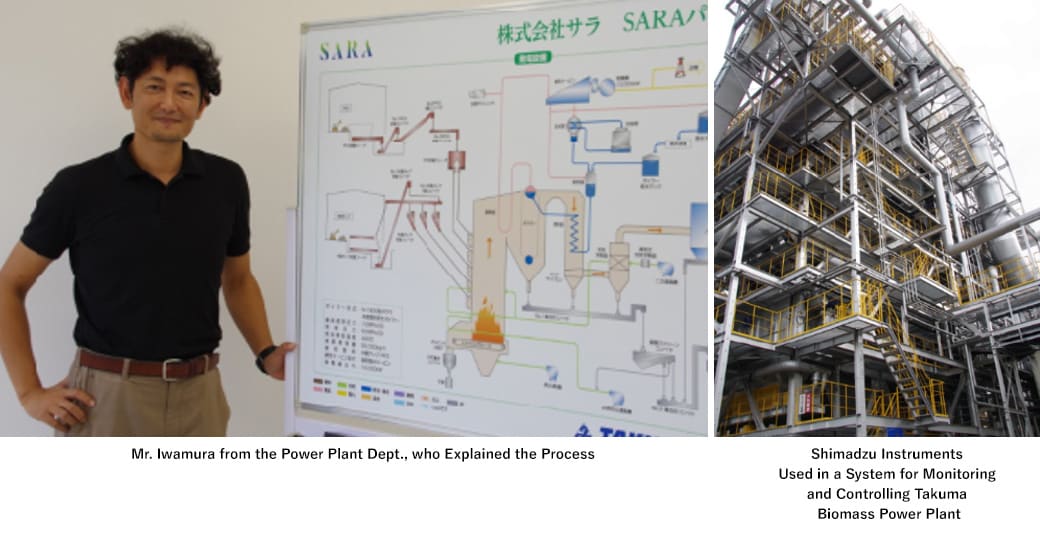

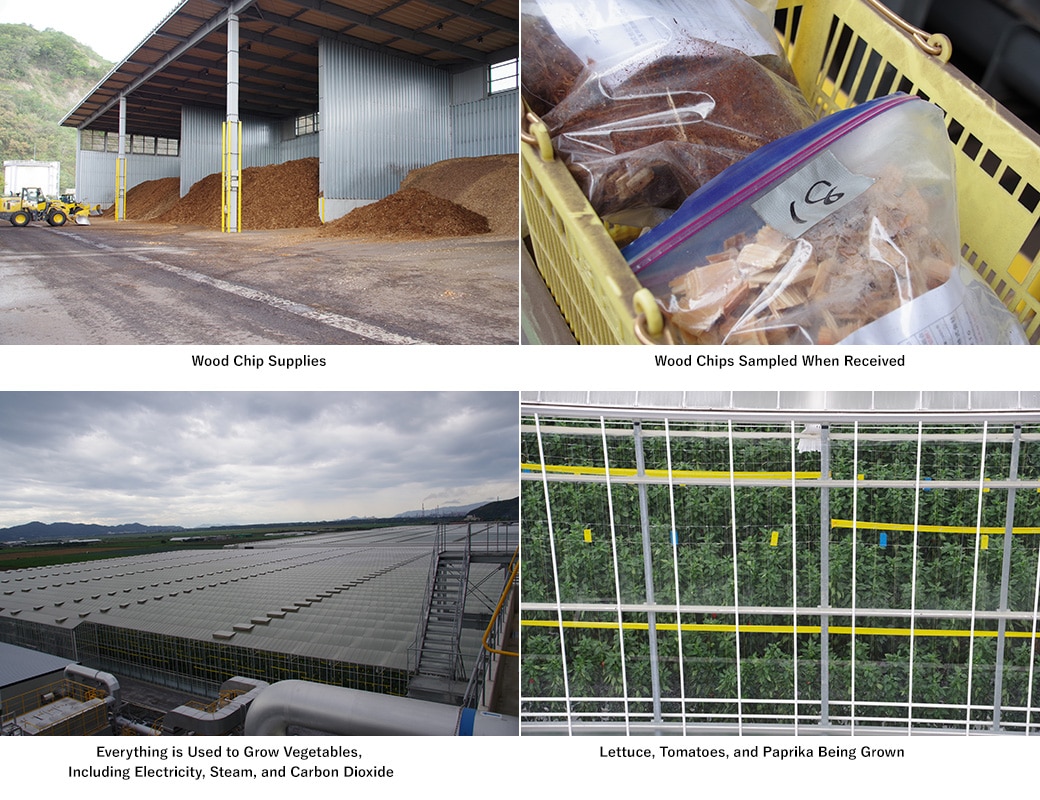

SARA Inc. in Kasaoka City, Okayama Prefecture, was established in 2016 near the Seto Inland Sea as a “vegetable company of the future,” for the purpose of using horticultural technology and renewable energy to produce a stable supply of delicious vegetables that can be eaten safely and worry-free. On the approximately 18-hectare site, the company built a biomass power generation plant and a 13-hectare semi-closed greenhouse, which is the largest in Japan. There it runs the most advanced and extensive smart-agriculture operation in Japan. The power plant, which has been in operation since April 1, 2019, generates electricity by burning wood chips that are mainly produced locally in Okayama Prefecture. Not only is the electricity used to produce vegetables, but the steam generated as a byproduct is also used as a heat source for providing the heating, humidification, and cooling necessary for growing vegetables. Even the carbon dioxide generated from the combustion gases is utilized for vegetable cultivation. Extra electricity generated from such circular and sustainable operating practices is redistributed by the Chugoku Electric Power Co., Inc. and supplied as electric power in the region.

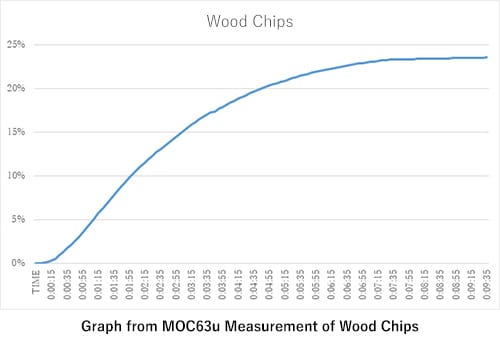

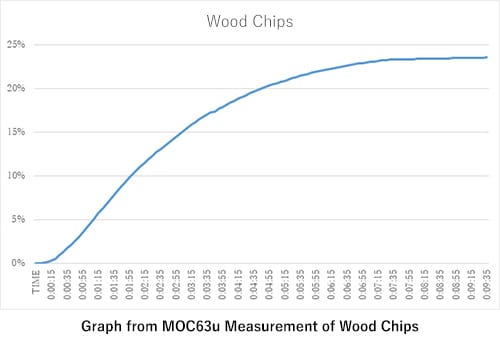

One important factor when generating electricity from woody biomass is the moisture content of the wood chips. Since this can have a major effect on the ignition performance, flammability, and amount of heat generated, some power plants measure the moisture content of chips when they are received to determine the price per unit based on combustion efficiency. The method used involves drying the chips for a given period in a temperature-controlled chamber and determining the moisture content based on the weight difference before and after drying. Then those results are input into a laptop computer. Consequently, the process requires many manual steps that are a potential source of human error.

In contrast, the measurement can be accomplished in only tens of minutes using a Shimadzu MOC63u electronic moisture analyzer, instead of over ten hours in some cases for the tedious conventional measurement process. The moisture analyzer can also send measurement data directly to a computer, which saves the time required for inputting data and ensures data can be acquired quickly and accurately.

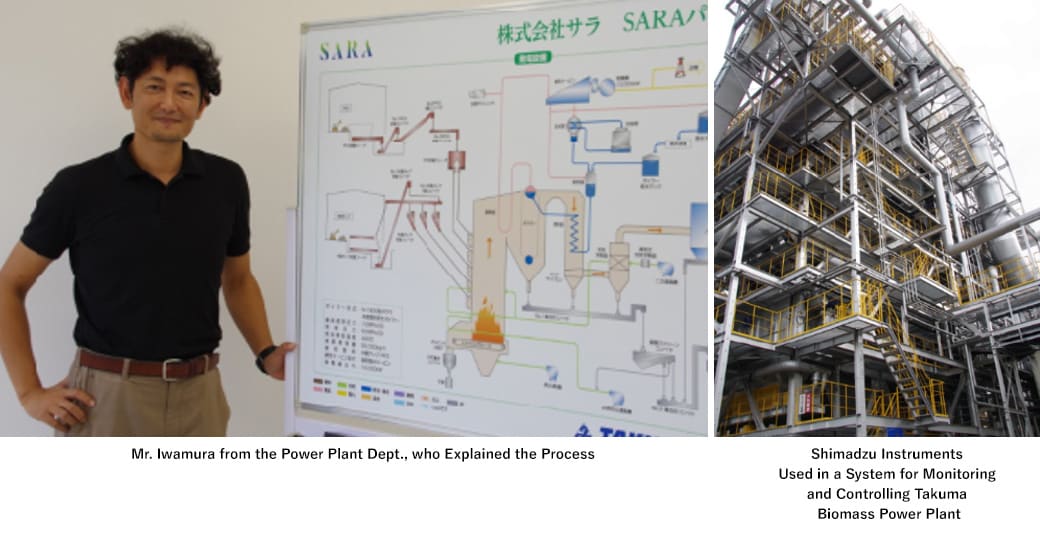

When biomass material is delivered, SARA samples the wood chips, branches, and leaves and uses a Shimadzu moisture analyzer to measure the moisture content. Yasuo Iwamura from the Power Plant Dept., who explained the process, said, “We just started operating the power plant in April, so currently we measure the moisture content of all deliveries in order to accumulate more data. We use six moisture analyzers to measure deliveries of about 20 types of wood chips and other fuels each day. Later, we intend to use that data for maintaining quality.”

(Interview held on Oct. 3, 2019)