GCMS-QP2020 NX

INDUSTRY

Biofuels and Biomass

KEYWORD

INTRODUCTION SERVICE&PRODUCTS

GCMS-QP2020 NX, Nexis™ GC-2030, i-Series

Perhaps you have heard of the term “bio-manufacturing.”

Biomanufacturing refers to the use of genetic technology to manufacture things, such as new kinds of materials, or to increase the yield of target materials produced by microorganisms. The research in this field that is being conducted around the world will lead to a shift away from dependence on fossil fuels and lead to resource autonomy. This will, in turn, result in solutions to global-scale societal issues, such as ocean pollution and food and resource shortages, while simultaneously achieve economic growth.

In this issue, we spoke with Tomokazu Shirai, Senior Scientist, Cell Factory Research Team, Center for Sustainable Resource Science, RIKEN, who is researching the use of microorganisms to produce hydrocarbon-free products.

Tomokazu Shirai Ph.D.

Senior Research Scientist

Cell Factory Research Team

*Affiliates and titles of the interviewee are current as of the time of reporting.

RIKEN Center for Sustainable Resource Science

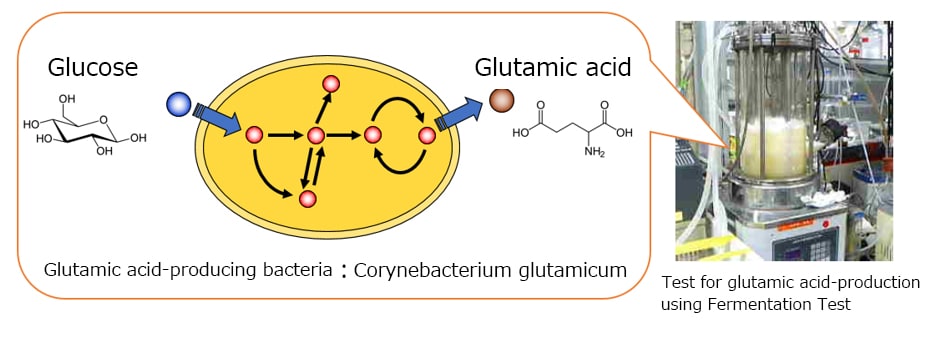

I began my research in my fourth year at university, investigating microorganisms that produce amino acids. I fed the microorganisms sugar as food, and they fermented it to create glutamic acid, a type of amino acid.

This fermentation involves about 15 to 20 different metabolic (chemical reaction) steps. Microorganisms not only make this glutamate but also possess various chemical reaction pathways (metabolic pathways) to maintain biological functions. It was necessary to quantitatively analyze these pathways, which were unclear at the time.

(Source: RIKEN Center for Sustainable Resource Science)

(Source: RIKEN Center for Sustainable Resource Science)

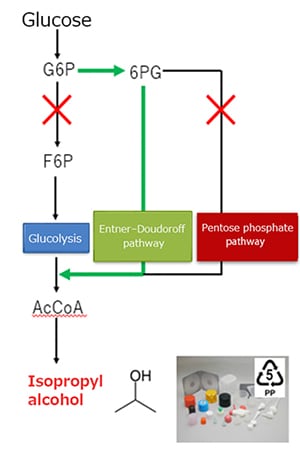

Producing Isopropyl Alcohol (IPA) from Glucose

(Source: RIKEN Center for Sustainable Resource Science)

Metabolic flux analysis is a technique used to study complex metabolic reaction pathways. This involves labeling cells with the stable isotope of carbon, 13C, to determine the flow, branching, and rate of metabolic reactions within the cell, which are then analyzed quantitatively using a gas chromatograph mass spectrometer (GCMS) and nuclear magnetic resonator (NMR). In addition, a high-performance liquid chromatograph (HPLC) is used to examine cellular by-products. Analysis is essential for our metabolic analysis and cell-based experiments and manufacturing, and analytical instruments are indispensable for this purpose. This has not changed at all since I started conducting this research.

My research focus has shifted from the production of amino acids that I studied at university to the production of raw materials for hydrocarbon-free products that I study today, but the fundamentals have not changed.

After graduate school, I worked as a researcher and then joined Mitsui Chemicals, Inc., where I developed technology to make isopropyl alcohol (IPA), a raw material for polypropylene (PP), using E. coli bacteria.

I then joined RIKEN, where I am currently employed, to pursue research on the direct bio-production of propylene.

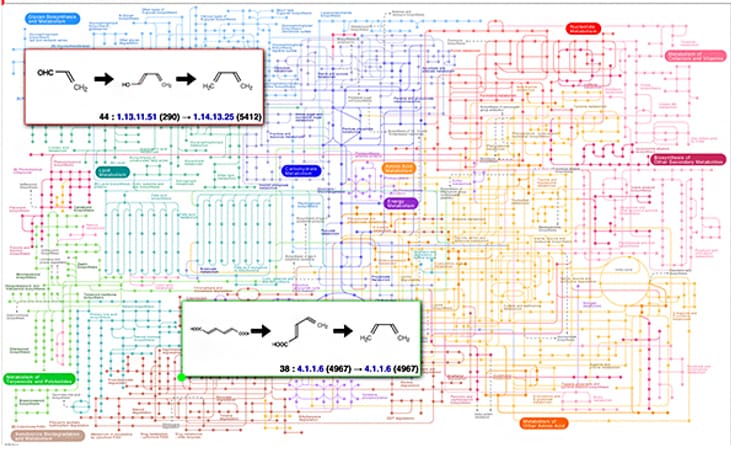

My new challenge is making something that used to be made from hydrocarbons with biomass materials derived from living organisms, using combinations of enzymatic chemical reactions, such as dehydrating, oxidizing, and decarboxylating enzymes. However, the astronomical number of combinations to be considered makes solving this problem extremely difficult and takes an enormous amount of time for a human to figure out. Therefore, we spent about five years developing BioProV, a simulation tool that can automatically predict and design metabolic reactions based on these patterns.

Candidate Pathways Identified by the “BioProV” Simulation Tool

(Source: RIKEN Center for Sustainable Resource Science)

This tool not only allows us to calculate the various possible enzyme reactions but also allows us to study the experimental results obtained from the calculations. The greatest advantage of the tool is that wrong reactions can be corrected, impossible reactions can be eliminated, and so on. However, not everything can be accomplished solely by a computer. Actual biotech-based experiments, such as creating enzymes based on pathways designed using the simulation tools and putting them into yeast, are essential. This is where analytical techniques become indispensable.

DBTL cycle

tIt is essential to conduct biotechnology experiments to create the enzymes based on the pathways designed using simulations. This is called synthetic biology, and its development cycle is called the “DBTL cycle,” an acronym for design (D: genetic design), build (B: microorganism creation), test (T: evaluation of products), and learn (L: predictive learning). In my research, I create a design (D) using multiple design tools, including “BioProV,” to optimize metabolic pathways and then perform experiments by building (B) microorganisms that produce actual enzymes. Next, we test (T) to evaluate how efficiently the microorganisms produce the material. In the learn (L) step, we use the results to enable the simulation software to learn and further optimize the design of the pathway. One of my strengths is that I have a background in applied biology, which allows me to understand the whole picture.

Companies face the possibility of losing market share in Europe if they continue to use exclusively hydrocarbon-based raw materials for plastic. In addition, they need to be more environmentally responsible due to shareholder demands. As a result, the application of biomanufacturing to these issues needs to be urgently accelerated. Although it will be difficult to replace all plastics with non-hydrocarbon-derived materials in terms of production volume and cost, I feel it is my responsibility as a scientist to promote research in Japan, where hydrocarbons are not easily extracted, so society is not reliant on fossil-based materials.

I have been using Shimadzu analytical instruments since I was a student.

With a Shimadzu high-performance liquid chromatograph (HPLC), actual samples that could not be measured by other companies’ products can be measured properly, and I believe the results are due to Shimadzu’s sophisticated technologies, such as the cooling system and lack of contamination. We are very satisfied with the cost of the annual maintenance, responsiveness, and the excellent level of service in English as well as Japanese since part-time researchers and foreign students are often involved in analyzing the data. The fact that you consider and respond to our requests as soon as we consult with you is also very helpful.

Currently, the automation of the “DBTL cycle” is being explored for synthetic biology development work. I am hoping that Shimadzu Corporation, which already provides analytical instruments, will move forward with robotics in the T (Test) area.

Many Shimadzu products are used in the laboratory, including the LCMS-8050, LCMS-8040, GCMS-QP2020 NX, GC-2030, and LC-2040Plus. Thank you very much for this very valuable discussion.