Basic Knowledge of Furnacees

Terminology

| A - C | ●Aging ●Annealing ●Binder ●Brazing ●Cascade Control ●CIM ●Contamination |

|---|---|

| D - H | ●Dewaxing ●Fine Ceramics ●Firing ●Graphite ●Hot Press |

| M - R | ●Metallizing ●MIM ●Powder Injection Molding(MIM, CIM) ●Purification ●Quenching ●Reduced Pressure Flow |

| S - T | ●Semi-Firing ●Semi-Sintering ●Sintering ●Solution Treatment ●Superhard Alloys ●Tempering ●Tight Box |

Heat Treatment

Heat treatment refers to combining various heating and cooling processes to obtain desired properties in a material. In other words, heating and cooling causes material transformations that improve material characteristics.

Important Treatment Factors Include:

- Temperature

- Treatment Environment (type of gas)

- Heating and Cooling Rates (required temperature range)

- Pressure (gas pressure)

- Treatment Environment (type of gas)

Vacuum

In this case, vacuum does not refer to a state where there is no atmosphere at all (absolute vacuum), but rather, is simply a specific space where the gas pressure is less than atmospheric pressure. As a result, the degree or level of vacuum is quantified in terms of pressure.

[Key Things to Know About Vacuums]

Difference Between Absolute Pressure and Gauge Pressure

Pressures are expressed in terms of absolute pressure and gauge pressure. Absolute pressure is the current pressure relative to absolute vacuum (if absolutely no atmosphere is present, i.e. zero). Therefore, there is no such thing as negative absolute pressure.

In contrast, gauge pressure is the current pressure relative to atmospheric pressure being zero. Vacuums are usually expressed in terms of absolute pressure, and the degree of increasing pressure is expressed in terms of gauge pressure. In both cases, the SI unit for pressure is pascals (Pa), however, in this discussion, to clearly differentiate between absolute and gauge pressures, absolute values are indicated as Pa·A and gauge values as Pa·G.

Vacuum Heat Treatment Furnace

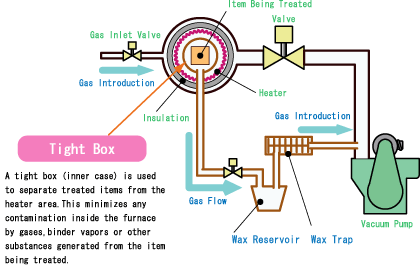

A vacuum heat treatment furnace first evacuates a particular space, then heats or cools the space. Key components of this furnace are shown below.

Advantages of Heat Treating in a Vacuum

- Heating an item in a vacuum reduces oxidation.

- Since a vacuum pump evacuates the space as the item is heated, all gases attached to the item can be removed.

Shimadzu Vacuum Heat Treatment Furnaces

Tight Box

A tight box (inner case) is used to separate treated items from the heater area. This minimizes any contamination inside the furnace by gases , binder vapors or other substances generated from the item being treated.

Aging

Process used to stabilize or promote changes in the properties or state of item being treated. Aging at ambient temperatures is called natural aging and aging at elevated temperatures is called artificial aging. After quenching, gauges and other such items which cannot have dimensional inaccuracies are artificially aged at 100°C to 200°C.

Annealing

Process where steel is heated to a suitable temperature, held at that temperature, then slowly cooled. The purpose of annealing is to relieve internal stresses, reduce hardness, increase machinability, improve cold workability, and modify the crystalline structure, or to obtain desirable mechanical, physical or other properties.

Binder

A collective term for the following types of materials used to bond ingredients together. Polymer or cement type of substances used to hold particles together and provide mechanical strength, uniformity in bonding, hardening, or to add increased viscosity to surface coatings. Used to adhere foreign substances. In ceramics, MIM and superhard alloy industries, "binder" refers not only to bonding agents, but also to composites containing simultaneously mixed lubricants and plasticizers.

Brazing

Method of bonding metals by melting a metal brazing medium and drawing it into the space between the metals via a wetting phenomenon and capillary action. The melting point of the brazing medium must be lower than the metals being bonded. In principle, the metals being bonded are not melted, but in actuality a complicated boundary layer reaction occurs, such as an alloy layer forming at the boundary between the brazing medium and metal parts.

Cascade Control

See Cascade Control.

CIM

Contamination

These are unwanted substances resulting from the heat treatment processes.Shimadzu furnaces can collect contaminants using a wax trap, dust catcher, and other features.

Dewaxing

Heating process that removes any organic binding agents used for molding. Paraffin or other organic binders are added to powder mixtures to reduce tooling wear during molding and maintain the strength of the molded item (green body). These substances decompose to soot when heated to high temperatures, can degrade the properties of the product, and must therefore be eliminated. The dewaxing process eliminates these binders by gradually heating the green body to a temperature below where the binder will decompose into soot and, thus, volatilizes the binders. Synonyms: Dewaxing, dewaxing, deparaffining

Fine Ceramics

Firing

Dissociates and eliminates unstable substances in molded objects (such as water crystals, chlorides or binders), then promotes reaction between all ingredients and forms them into a stable compound. Simultaneously, a sintering process occurs that shrinks and densifies the object. This results in a sintered object of fixed shape and strength. Sintering non-metallic objects is often referred to as firing.

Graphite

An allotrope of carbon, graphite is extremely heat resistant and used inside Shimadzu furnaces (such as for heaters and insulation).

Hot Press

Filling a steel die with powder or a green body and heating it under pressure will promote the diffusion of ions and atoms from stresses and produces a high density sintered body at low temperatures. There is a limit to the types of die steels and operating parameters, but this process is used for items with compositions that are difficult to densify or to densify an item quickly. The main advantage of this method is that sintering can be performed at lower temperatures, so grain growth is less likely to occur. This results in a dense product formed from fine particles. It also refers to the process of applying pressure during heating. Shimadzu presses can apply vacuum treatment during this process as well.

Metallizing

Refers to the bonding of ceramic and metals. Normally performed using solid-gas phase systems, solid-liquid phase systems, or solid-solid phase systems.

MIM

Powder Injection Molding(MIM,CIM)

Used to mold metals in the same way as plastics are molded, this process allows the accurate molding of complicated shapes at near net shape (approximately the shape of the finished product) in production. Injecting metal powders is referred to as MIM (metal injection molding) and injecting ceramic powders is referred to as CIM (ceramic injection molding).

Purification

The amount of dissolved gasses in a product varies depending on the pressure and temperature. These gases can be degassed by heating the product under vacuum for a long period of time. Purification can be performed more aggressively by introducing purification grade chlorine or hydrogen chloride gas.

Quenching

Process of hardening an item by rapidly cooling it from the austenitic temperature. It also refers to simply the process of rapidly cooling an item. Rapidly cooled steels will harden by changing to a martensite structure. If cooled slowly, steel will transition to troostite, sorbite and pearlite, in that order, and become softer.

Reduced Pressure Flow

Gas is injected into the furnace and simultaneously the vacuum pump reduces the pressure inside the tight box. This results in gas flowing into the tight box from the outside and being evacuated from the box's interior. This minimizes the chance of any gases or other substances generated from the item being treated being diffused back into the furnace. This is used primarily for degassing and dewaxing processes.

Semi-Firing

Preliminary firing process performed at a temperature below the final firing temperature. Purpose is to make the raw material's powder distribution more uniform, to debind the green body, or increase the strength of the material.

Semi-Sintering

Preliminary firing process performed at a temperature below the final burn-in temperature. Purpose is to make the raw material's powder distribution more uniform, to debind the green body, or increase the strength of the material.

Sintering

Molded metallic or non-metallic powder is heated to less than its melting point, or to a temperature where a small quantity may exist as a liquid, so that the powder becomes bonded or fused together. This produces a solid with a certain amount of strength and other characteristics. When powders are merely pressed together, the total surface energy is not at its lowest state and is out of equilibrium. Heat treating causes mass transfer to occur in the direction of reducing surface energy. In other words, the surface area decreases as the powder particles bond. Factors that affect sintering include the particle size, chemical composition, heating temperature, heating time, sintering environment, purity, and compressive pressure.

Solution Treatment

Multi-step process of heating metal alloy components above where they would melt into a solid solution, then after holding them at that temperature for an extended period, rapidly cooling the alloy to inhibit the precipitation process. This is the fundamental heat treatment process for austenitic stainless steels, which changes the brittle phase, such as in carbon-chromium steels or the sigma phase, into a solid solution and eliminates residual strain from machining.

Superhard Alloys

Broadly speaking, a term that refers to composite alloys made of hard particles of carbon, nitrogen, carbonitride, or other such compounds, alloyed with iron-group metals, such as Fe, Co, Ni, or an alloy thereof. However, this term usually refers to alloys of primarily WC-Co.

Tempering

Process that promotes transformation or precipitation processes in quenched structures to improve stability and imbue them with the desired properties and characteristics. It is also used after the annealing process. The purpose is to improve notch toughness and prevent stress cracking problems that would tend to occur if quenched without tempering.

Tight Box

Cylindrical chamber made of graphite or heat resistant metal (some are square). This chamber separates the item being treated from the heater and insulation areas to prevent gases or binder vapors generated by the item from contaminating furnace interior surfaces.