Summary

KPR-300 is a V-block method (Vee-block or Hilger-Chance method) with a reputation for measuring the refractive index of optical glass and plastic. KPR-300 can measure the refractive index of a small sample or resin material that can not be measured with a spectrometer(Minimum deviation method).

For molded lenses used for smartphones and others, the refractive index varies depending on the thermal history during molding. Therefore, management based on measured values is important for quality control.

It can be used for material development, quality control at the time of material manufacturing, and acquisition of necessary information to design optimized for use conditions.

Related information: Refractive index and dispersion of optical glass

Measurement example

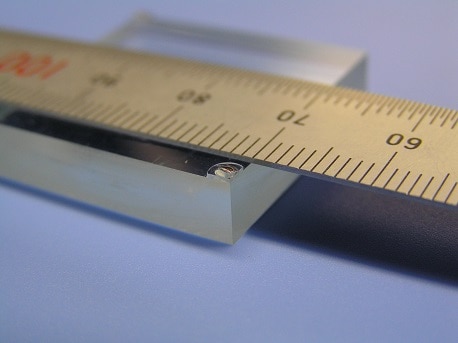

Fig1. Small diameter lens fixed to the base (after processing)

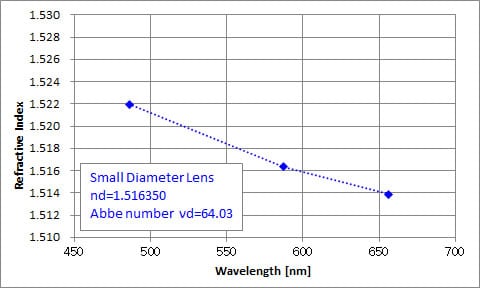

Fig2. Refractive index measurement result of small diameter lens

※It is a typical value obtained by this measurement. It does not guarantee the refractive index and the Abbe number of each sample.

Equipment configuration

| No | Item | Note |

|---|---|---|

| 1 | Refractometer KPR-300 | |

| 2 | V-Block Prism 516-641A (nd = 1.52) | |

| 3 | Contact liquid nd 1.52 |