Elevating experimental design through automation

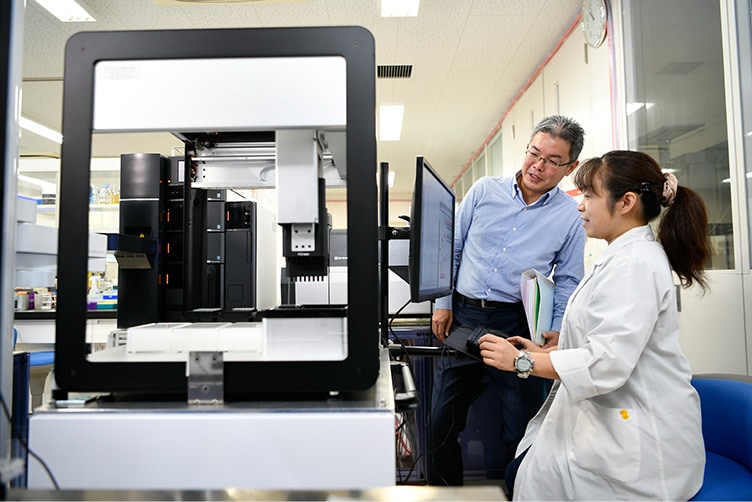

Tomohisa Hasunuma (standing) at the Autonomous Lab System at Kobe University.

Smart cells — biological organisms, such as microbes, artificially modified using techniques from synthetic biology — hold significant promise as tools in the mass production of raw materials for renewable energy and functional foods, that are difficult to realize through other means.

“They could trigger a technological revolution in a variety of areas, such as pharmaceuticals, foods, new materials, environmental remediation or alternative materials for petrochemical products,” says Tomohisa Hasunuma, director of the Engineering Biology Research Center at Kobe University, Japan.

However, there are significant challenges in the experimental design process — including reliable data acquisition, analysis, and speed — that need to be overcome to move from the design and optimization of these ‘smart cells’ in biofoundries, through to commercial-scale, industrial application. In 2016, to solve these challenges Hasunuma partnered with engineers from a precision instrument manufacturer, Shimadzu Corp, in Kyoto, Japan.

“The stability and robustness of analytical instruments are important in the “test” phase of design-build-test-learn (DBTL) cycles of smart cell development in biofoundries”, says Taichi Tomono, a lead research scientist at Shimadzu.

Automated design

Harnessing smart cells, such as microbes, to produce industrially important compounds involves tinkering with their metabolism by tweaking genes, which is typically a laborious process. Coming up with a system to automate the process and incorporate the power of artificial intelligence is a vital step for making the technology commercially viable.

Microbiologists at Kobe University, in conjunction with Shimadzu, have developed an automated experimental system to optimize all the parameters. It is based on DBTL cycles, in which each of the four steps is automated. “A microbe is designed on a computer, a robot is then used to create the microbe, and the robot is used again to test the performance of the microbe,” says Tomono. “And finally, the results of testing the microbe are fed into machine learning, which is used to enhance the original design.”

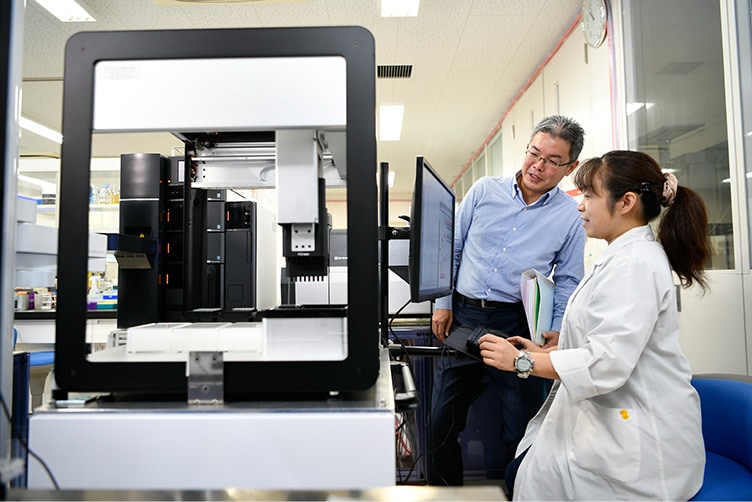

A test in progress using Shimadzu's design-build-test-learn (DBTL) system.

This system can greatly accelerate research and development of biofoundries. “We have developed a technology to design metabolic pathways to increase the production by using a computer to perform the design,” says Hasunuma. “It can produce somewhere between 1,000 and 2,000 strains of microorganisms in a single experiment.”

Unique strengths

Hasunuma notes that while other groups are developing DBTL systems, Kobe University can incorporate long snippets of DNA in microbes. “This allows us to quickly create extensive libraries of strains,” he says.

Meanwhile, Shimadzu’s strong point is the state-of-the-art analytic system. “The system contains a world-class mass spectrometer, enabling us to accurately evaluate microorganisms in the biofoundry,” says Hasunuma. “This is important since it is critical to evaluate whether the enzymes are functioning properly in the microbial cells and whether the metabolic pathways are being used correctly.”

Importantly, the liquid chromatography employs robots. “Shimadzu and Kobe University have collaborated to develop the world’s first pretreatment robot, which automatically removes cells from the bioreactor, extracts metabolites from cells, and sends them to the mass spectrometer for analysis,” says Hasunuma.

Accelerating the process

The metabolite-extraction system can analyse 186 metabolites simultaneously, while the high-throughput evaluation system can rapidly find promising smart cell candidates. Combining these two systems will facilitate the mass production of highly functional substances on a much faster time scale than is possible using conventional techniques.

The entire process, from experiment proposal to results management, is completely integrated. Shimadzu engineers designed a dedicated process management app that depicts the entire experiment process flow visually and uses simple and intuitive operations to specify process steps via the cloud.

“Without learning complex programming languages, anyone can easily create and understand experimental protocols,” says Tomono. It also stores information about each sample, such as the containers, instruments, reagents, and analytical techniques used, and manages it together with experimental results in a database to ensure high traceability. All data related to an experiment can be analysed and viewed using the app.

A prototype of Shimadzu's Autonomous Lab System.

Artificial intelligence (AI) is used to propose new experimental conditions based on the previous experimental results. Finally, visual programming and functional modules make it easy to design experimental protocols. “The system, including our mass spectrometers, can be easily reconfigured using visual programming, just like assembling Lego bricks,” says Tomono. “So, for example, if you wanted to test various strains of microorganisms in a biofoundry, you can quickly reconfigure the equipment for testing.”

These distinctive aspects result in a powerful system with the ability to greatly accelerate the development of useful strains of microbes. “Our DBTL system is unique compared to other systems in the world,” says Hasunuma. “It will greatly reduce the time needed to develop a recombinant microorganism requested by a client, making it a very potent tool for commercializing the manufacturing of compounds using microorganisms”

A host of possibilities

The use of the smart cell system for new materials is just the tip of the iceberg when it comes to applications. “By combining robotic, digital, AI, and other technologies, we’ve developed an autonomous laboratory system for developing smart cells, which has the potential for wide application,” says Tomono.

Masahiro Ikegami, a researcher at Shimadzu is also excited about its potential. “Further development of this smart cell technology could see it used in areas such as health care and agriculture,” he says. “For example, it could be used to cultivate new cells for use in gene therapy or produce supplements, biofuels and various materials.”

Like all successful collaborations, the partnership draws on the strengths of both parties. “Kobe University’s strength is that we are able to create various kinds of recombinant microorganisms. We have a lot of experience in making useful microbes,” says Hasunuma. “Shimadzu offers excellent analytical technologies, including system development, automation, data management, and data analysis. These are used to assess the microbes.”

Ultimately, this work is in-line with Shimadzu’ grand vision of an Autonomous Lab. The company envisages a system where a researcher first enters a protocol (experiment procedure) via a cloud service. Then a robot executes the experiment and sends the results back to the researcher. “We want to advance research and development towards a future lab vision where robots and AI can autonomously achieve scientific discoveries,” says Tomono.

For now, the Shimadzu-Kobe team is focusing on verifying the utility of the Autonomous Lab prototype system through, which will contribute to the development of smart cells, and hopefully, early implementation in society, says Tomono. A partnership that leverages the strengths of academia and industry makes Kobe University's DBTL cycle and biofoundry unique. “Biofoundries harnessing smart cells have immense potential,” says Hasunuma.

The text of this article was originally produced in partnership with Nature Portfolio as an advertisement feature. It was published on 14 November 2023 in the online version of Nature (nature.com), a weekly international journal, publishing the finest peer-reviewed research in science and technology. (https://www.nature.com/articles/d42473-023-00246-x)

Copied

Copied