vol.3

The dream of “Made in Japan”

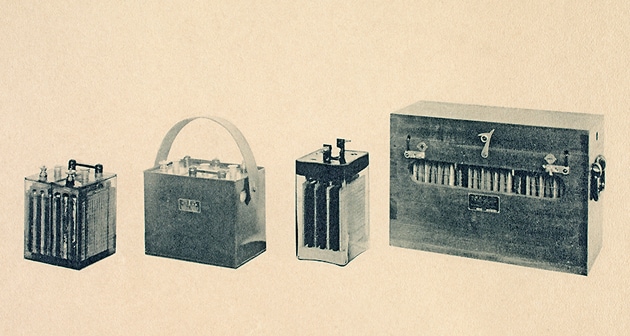

Mention car batteries and it’s not surprising that many people think of the two letters “GS”.

The initials “GS” in GS Yuasa batteries, famous even today, actually stand for Genzo Shimadzu.

2008 marked the 100th anniversary of the registration of this trademark.

It’s no exaggeration to say that Umejiro Shimadzu, later Genzo Shimadzu Jr., is the forefather of modern industry in Kyoto.

He was a genius at invention, has been called Japan’s Edison, and is admired as a scientist and engineer even today. What initially inspired this genius at invention was a casual comment by his father, Genzo Shimadzu Sr. When Genzo Jr. was small, the equipment brought one after another to Shimadzu for repairs was all foreign made.

The boy Umejiro asked his father, “Why can’t Japanese make machinery like this?”

“It’s not that we can’t make them, it’s that we have no one that has studied manufacturing equipment.”

This reply inspired the young boy.

Because he had been recruited to help with the family business, he had only attended two years of school.

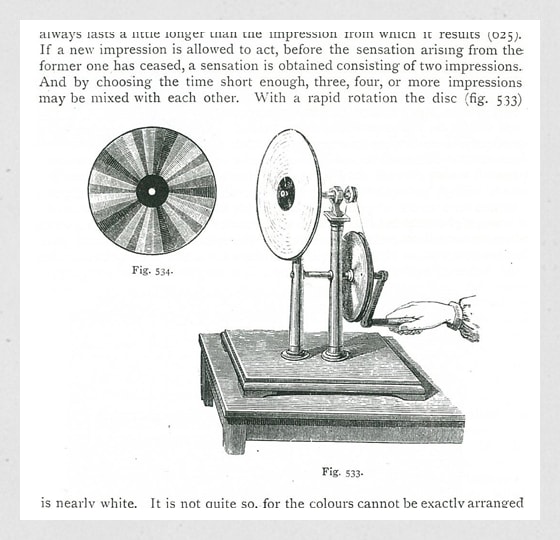

Instead of a formal education, he studied on his own with French physics texts that he borrowed from his father.

Needless to say, he could not read any French. Using only the illustrations and diagrams as a reference however, he managed to recreate the machines, with screws, pulleys, shafts, and handles exactly as shown in the science text. This pleased his father, and surprised everyone around him.

Though Genzo registered 178 patents during his lifetime, perhaps the most representative was a method for manufacturing reactive lead powder, a material used for manufacturing storage batteries.

(English version)

Japanese industry entered a growth period from the middle of the Meiji period (1868 to 1912). During this time, manually driven machines were replaced by electrically powered machines.

Facilities for generating electricity were still inadequate, so there was a surge in demand for storage batteries for use in radio communications, railroads, and theaters.

Based on foreign models, Genzo also started manufacturing storage batteries. Then in 1897 (Meiji 30), he created a paste-type lead storage battery with a 10 ampere-hour capacity. This marked the beginning of the industrial production of storage batteries in Japan.

In 1908 (Meiji 41) he launched the GS brand, and then established Japan Storage Battery Co., Ltd. in 1917 (Taisho 6).

The most important material for storage batteries was lead powder, but the technology for grinding the lead into powder was not available in Japan at that time.

The future of his new company hinged on whether it could make good quality lead powder. This meant either buying the technology from the leading company at the time, Tudor in Germany, or developing new technology themselves.

After overruling the executive board and choosing the latter course, Genzo went to visit Dr. Ueda at the Imperial Ceramic Experimental Institute in Kyoto. He did this in order to borrow a ceramic powder mill for his experiments.

After being refused on dozens of occasions, he was finally able to borrow the powder mill. However, the resulting power was too coarse and could not be used.

In fact, he even overheard from one of the Japan Battery employees that Dr. Ueda had said, “your president has no understanding of chemistry”.

But one day, continuing by trial and error, Genzo happened to notice the powder clinging to the opening where the material was added to the machine. This lead powder was as fine as dust and of good quality.

“This must be due to the air flow,” he reasoned.

That was the moment he discovered how to produce lead suboxide by aerating the powder mill.

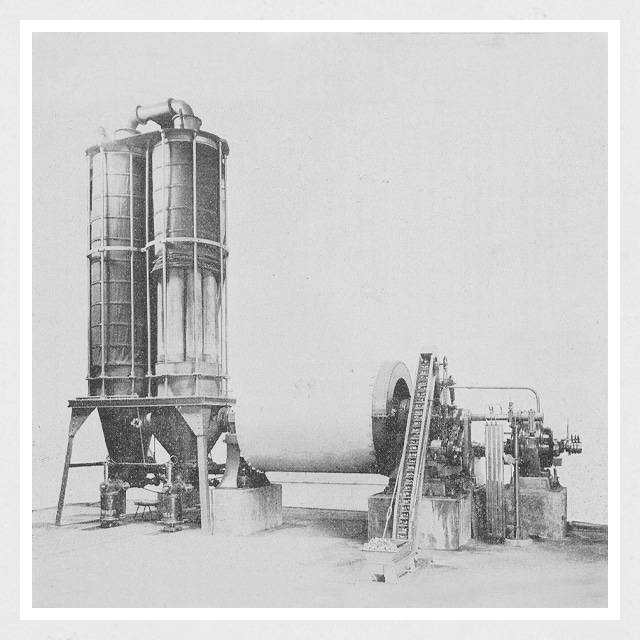

This method for manufacturing reactive lead powder produced much higher-quality powder, enabling large-scale production.

The manufacturing method was so revolutionary however that it took three years to be patented because it was considered inconsistent with common knowledge.

Genzo was probably often at war with common knowledge.

The common knowledge that technology is something purchased from overseas.

The common knowledge that foreign products are the best.

No doubt, Genzo never forgot the words of his father when he was a young boy.

What would Genzo think of our current day and age, now that “Made in Japan” is considered a mark of quality?