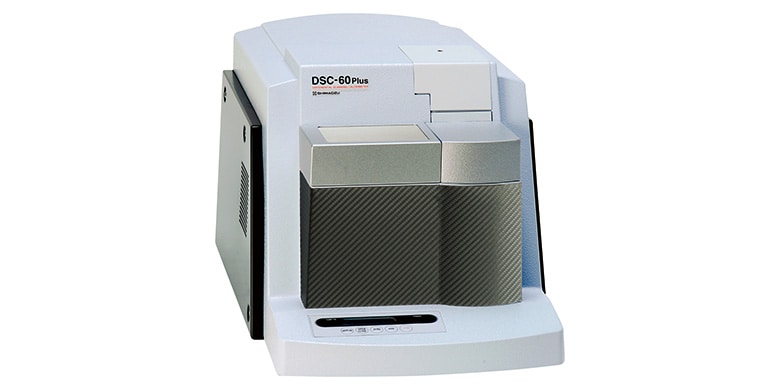

DSC-60 Plus Series

- By measuring the oxidation induction time using a DSC, the degree of deterioration and the effects of antioxidants in rubbers, plastics, and other materials can be evaluated. - By using ”OIT Automatic Termination Software,” measurements can be stopped and oxidation induction time analyzed automatically.

Polymer materials, such as rubbers and plastics, absorb oxygen in the air during molding and use. As the oxidation reaction proceeds, it can cause various deterioration phenomena. Therefore, antioxidants or other additives are generally added to polymer materials to prevent oxidative deterioration. Evaluation of the effectiveness of antioxidants, resistance to heat and light, and the degree of deterioration is extremely important at the development and manufacturing stages. The effect of additives and the degree of deterioration can be evaluated by measuring the oxidation induction time (OIT) with a differential scanning calorimeter DSC. This paper describes the results of measuring oxidation induction time in polypropylene that has been deteriorated by heat treatment for different periods or deteriorated by irradiation with ultraviolet rays.

February 3, 2022 GMT

Some products may be updated to newer models