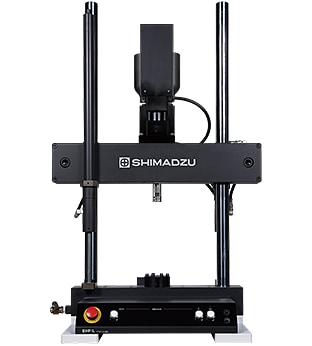

EHF-L Series

- It is possible to evaluate fatigue of carbon fiber reinforced thermoplastic (CFRTP) by using the Dynamic and Fatigue Testing System Servopulser, EHF-L Series and newly developed gripping teeth for composite materials. - High-accuracy dynamic control can be achieved with the Servo Controller 4830.

Carbon fiber-reinforced plastic (CFRP) has a higher specific strength and stiffness than metallic materials and is expected to contribute to reducing the weight of transport equipment. On the other hand, it faces issues such as complicated manufacturing, processing, and recycling, along with high costs, which restrict its application to aircraft and specific types of transport vehicles. Carbon fiber-reinforced thermoplastic (CFRTP) has attracted attention as a material that could solve these issues. Thermoplastic resin, which is the base material of CFRTP, softens when heated and hardens when cooled, making it suitable for mass production such as injection molding and press molding. Due to its high moldability, it offers excellent cost performance and recyclability, and is expected to be used in mass-produced automobiles. However, when it is used as a structural material for automobiles, it is often subjected to repeated loads over long periods, which may cause fatigue failure. In particular, fatigue failure in transportation equipment has the risk of causing a serious accident, so appropriate evaluation by fatigue tests is necessary to ensure product reliability. In tests on composite materials, it was easy for failure to occur from defects or notches, and clamps with conventional file teeth tended to cause failures at the grips. In this article, fatigue tests were conducted on CFRTP using newly developed gripping teeth for composite materials. The newly developed gripping teeth makes it possible to reduce damage to the test specimens and decrease the risk of failure at the grips.

October 7, 2025 GMT

Some products may be updated to newer models