Tensile Testing for PET Films

● Introduction

PET films are macromolecular films made from PET (polyethylene terephthalate) resin. Because this material offers excellent strength, heat resistance, and dimensional stability, it is used for industrial purposes and for packaging. It is also widely used for electronics, including magnetic tapes and film capacitors. In recent years, its use has been highlighted in functional films (protective films, anti-reflection films, and electromagnetic preventative films) for LCDs and plasma displays.

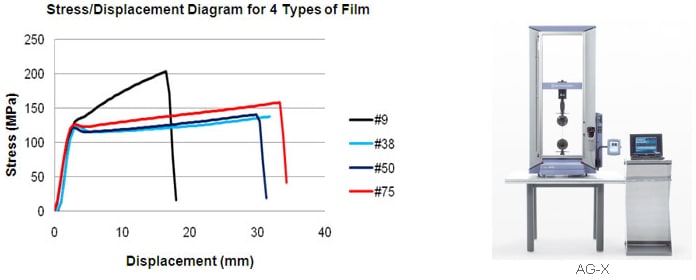

In this case, tensile tests were performed of PET films with different thicknesses.

● Test Conditions

|

Tester |

:AG-X table-top type |

|

Load cell |

:1 kN |

|

Grip |

:1 kN pneumatic flat type (grip faces are flat) |

|

Test speed |

:600 mm/min (10 mm/s) |

As preprocessing, the specimen was punched into a dumbbell shape before testing.

● Tension speed: 600 mm/min

|

Name

|

Maximum Point_Test Force

|

Tensile Strength

|

Break Point_Displacement

|

Break Point_Strain

|

|

Units

|

N | N/mm2 | mm | % |

|

9 μm

|

27.5 | 204 | 17.9 | 36 |

|

38 μm

|

85.3 | 150 | 39.4 | 78.7 |

|

50 μm

|

106 | 141 | 31.3 | 62.6 |

|

75 μm

|

178 | 158 | 34.3 | 68.6 |

● Test Conditions

Four types of film with different thicknesses (9µm, 38µm, 50µm, and 75µm) were tested. The resulting test force increased with the thickness of the film (see table). As evident from the stress graphs however, the high strength value was only for the 9µm sample. In addition, the 9µm sample had the smallest maximum elongation, while the others had similar, large values. The films must be drawn in order to thin them, but it appears that the 9µm sample from this test will lose elasticity during the drawing process, turning into a hard membrane.

● Conclusion

High functional resins including films come in many different varieties, and are involved in a number of research and development projects. Be sure to take advantage of the AG-X for the evaluation of high functional resins.

* Please be advised that data obtained before the implementation of the current Weights and Measures Law may be presented in terms of gravimetric unit.