Analysis of Rubber (GCMS)

The double-shot method was used to analyze tire rubber, which contains a number of additives. A combination of evolved gas analysis (EGA) and instantaneous thermal decomposition methods makes the qualification of these components easy.

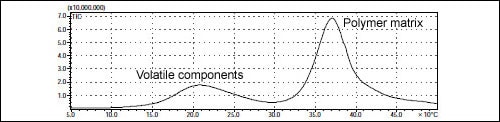

Evolved gas analysis (EGA) was performed at constant temperatures between 50 ºC and 500 ºC, where two peaks were detected (Fig. 1).The components in the first peak are volatile components, while the components in the second peak are the polymer matrix.

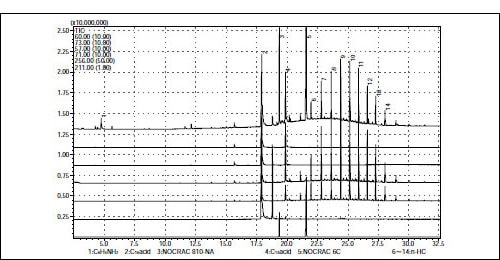

When using the normal instantaneous thermal decomposition method, these components appear at the same time, making their qualification difficult. Based on this EGA curve, the first thermal desorption conditions were set to 300 ºC (30 s) and the second instantaneous thermal decomposition conditions were set to 550 ºC (Fig. 2).

Fig. 1 Evolved Gas Curve for Tire Rubber

Fig. 2 Thermal Decomposition Chromatogram (300 ºC/30 s)

Pyrolysis GC/MS System

This system conducts GC/MS analysis of the products of thermal decomposition of polymer compounds such as plastics, rubber, and resins at decomposition temperatures of 500 °C and above.

The decomposition products reflect the structure of the original polymer compound. They permit the identification of the polymer and more sophisticated structural analysis. Database search software supports the identification of polymers.