Dry Measurement of Magnetic Particles

Dry measurement is used for measurement targets and purposes such as follows that cannot be met by wet measurement:

- Drugs and foods that cannot be measured by wet measurement due to their dissolving in water or a dispersion medium

- Samples, such as powder paints, that should be measured by dry measurement in consideration of their purpose and conditions of use

In addition to this, it has been found that dry measurement is also effective for measuring

- Magnetic particles, which easily aggregate in a liquid and are extremely difficult to disperse

In the development and quality control of high-performance motors and high-density storage media, it is extremely important to be able to accurately measure the particle size distribution of magnetic particles, which greatly influence the performance and quality of these products. To accurately measure particle size distribution on a laser diffraction particle size analyzer, first, the particle group to be measured must be dispersed uniformly in a medium.

However, it is extremely difficult to disperse a particle group comprising magnetic particles in a liquid down to the primary particles, and, even if the particle group could be successfully dispersed, it immediately aggregates again. Although re-aggregation can be suppressed if a highly viscous liquid medium is used, it is even more difficult to uniformly disperse the particle group in such a medium in the first place.

Accordingly, it can be said that accurately measuring the particle size distribution of a particle group that has quite strong magnetism is extremely difficult.

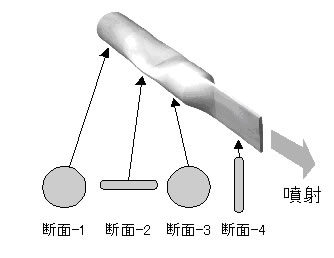

With injection type dry measurement, the particle group is effectively dispersed and injected by its cross-section and orientation being rapidly altered while the airflow containing that particle group passes through the nozzle in Fig. 1. Because the time from when the particle group is injected from the nozzle at high speed up to it passing through the laser beam and the diffracted/scattered light being detected is extremely short, it is considered that there is almost no possibility of the particle group re-aggregating during this period.

In addition, the possibility of the particle group aggregating during passage through the nozzle is also low since there are no parts on the nozzle in Fig. 1 where the cross-section has been extremely constricted (made smaller).

Fig. 1 Nozzle Suited to Measurement of Magnetic Particles

Fig. 2 shows the results of actually measuring hexagonal barium ferrite particles by the wet and dry methods as an example of measuring magnetic particles. Though particles could be measured successfully by dry measurement, the particle size increased about 10 times in wet measurement because the particles aggregated.

In this way, you can see that dry measurement is more suited to the measurement of magnetic particles than wet measurement.

Fig. 2 Measurement Results for Magnetic Particles