Using Microscope Accessories

Transmission Measurement with Infrared Microscope

When performing transmission measurement with an infrared microscope, the sample is flattened and measured using a transmission window plate. Transmission windows are made from various materials; the well-known types include those made from KBr, BaF2, diamond, and silicon wafer. The characteristics of these windows vary and are selected according to the actual measurement conditions.

1. KBr

Features: This is a commonly used type. It is relatively cheap and has an extremely high transmittance of 90 % for infrared light. (See Fig. 1.) The wide wave-number region of 4,000 to 400 cm-1 makes it possible to obtain high-quality spectra.

Points to note: It is relatively soft and prone to damage. KBr dissolves when used for samples containing moisture and is therefore unsuitable for measurement in this case. Store it at a humidity level not exceeding 50 %. If a KBr window plate is stored in a location with a high humidity level, because of deliquescence, the window will become clouded and it will not be possible to obtain high-quality spectra.

Fig. 1 Transmittance for Different Types of Window Material

2. BaF2

Features: This is a commonly used type. It is relatively cheap and has an extremely high transmittance of 90 % for infrared light. It has greater water-resistance than the KBr type.

Points to note: It is relatively soft and prone to damage. There is BaF2 absorption at wave numbers of less than 800 cm-1 and measurement is possible only down to approx. 720 cm-1. (See Fig. 1.) BaF2 dissolves when it is used for samples containing acid or ammonia.

3. Diamond

Features: This is a commonly used type. It is easy to handle. It is a very hard substance and is extremely resistant to damage. It is also relatively stable in terms of chemical behavior and can be used for various types of sample. It has a high transmittance of approx. 70 % for infrared light.

Points to note: It is more expensive than KBr and BaF2. The area for which measurement is possible is small and, when using relatively large samples, it is sometimes necessary to cut and set the sample for measurement. The edges of the window are not suitable for measurement. There is diamond absorption in a neighborhood of 2,000 cm-1 and the S/N ratio is lower in this range. (See Fig. 1.) Also, the refractive index of 2.4 is relatively high and the difference between that of general samples makes the appearance of interference fringes likely.

4. Silicon Wafer (High-Resistance Silicon Wafer)

Features: This type is not commonly used. It is relatively hard and easy to handle. Water can be used to clean it.

Points to note: It has a relatively low transmittance of approx. 55 % for infrared light, making it difficult to obtain high-quality spectra. It also has the disadvantage of not allowing transmission observation with visible light. Also, the refractive index of 3.4 is high and the large difference between that of samples makes the appearance of interference fringes likely.

It can be seen from the above that, as for the type of window plate used for transmission measurement performed with an infrared microscope, diamond is suitable for general-purpose and hard samples, and KBr and BaF2 are suitable for high-sensitivity analysis.

Using Diamond Cells (Points to Note When Flattening Samples)

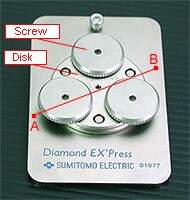

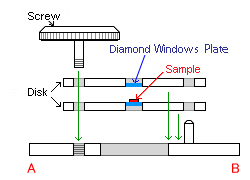

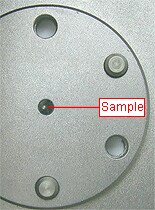

A diamond cell consists of two discs into which diamonds with dimensions of 2 to 3 mm are embedded. (See Figs. 2 and 3.) This accessory is useful for making hard or irregularly shaped samples thinner. Depending on the way it is used, however, it may not be possible to obtain high-quality spectra. Here I will describe how to use the diamond cell effectively.

Put an appropriate amount of the sample on a disk. Note that if an amount of the sample that could be spread out over the entire diamond cell is used, it will not be possible to perform background measurement.

Put the other disk on top of the sample to flatten it out.

With soft samples, simply pressing with your hand is sufficient; there is no need to use screws. With small, hard samples, flattening the sample by turning the screw with a large force may, in exceptional cases, cause cracks to appear at the edge of the diamond.

It may not be possible to obtain high-quality spectra if measurement is performed with the upper disk in place. For example, the infrared light passes through windows twice, which may adversely affect the transmittance; the large diamond absorbance may also adversely affect the transmittance; the direction of the light may become parallel between the disks, making the appearance of interference fringes extremely likely.

Therefore, remove the upper disk before measurement. Note that the sample may adhere to the upper disk.

Put the disk to which the sample has adhered in the holder and perform transmission measurement using an infrared microscope. (See Fig. 4.)

Clean the windows after use. A simple method is to scrape of any dust that has adhered to the windows using a swab that has been soaked in water or alcohol.

Fig. 2 Diamond Cell The sample is flattened out between two disks.

Fig. 3 Diamond Cell Structure (cross-sectional diagram at A-B in Fig. 2)

Fig. 4 Diamond Cell The disk with the sample is placed in the holder for measurements.