Shimadzu offers “Eco-Products Plus” products, which are products that are certified to achieve outstanding environmental performance. Certification criteria: Eco-Products Plus products must satisfy at least one of the following criteria compared to our previous models.

| Criterion | |

|---|---|

| 1 | At least 25 % lower energy consumption |

| 2 | At least 25 % smaller size (in terms of weight, volume, or footprint) |

| 3 | At least 25 % less use of consumables such as gases and solvents |

| 4 | At least 25 % reduction in CO2 emissions*1 based on life cycle assessment due to longer life |

| 5 | At least 25 % reduction in noise level*2 |

| 6 | At least 25 % improvement in energy density*3 |

- ※1:The CO2 emission reduction rate is calculated using the following formula.

(Total CO2 emissions during the life cycle of the partially renewed model / useful life year extended by the partially renewed model) ÷ (Total CO2 emissions during the life cycle of the conventional model / useful life year of the conventional model) - ※2:The noise level of a product that generates more than 40 dB of noise must be reduced by at least 25 %.

- ※3:Energy density is calculated as (rated pressure) × (rated flowrate).

In the case of a hydraulic pump, (rated flowrate) = (pump volume) × (rated rotation speed)

TMP-B300/B70 TurboMolecular Pumps

These compact pumps have excellent handling properties and are suitable for analytical instruments, general industrial machinery, and research applications. Features include high reliability, long service life, and a high H2 gas compression ratio, and they can be operated locally and mounted in any orientation.

Product Details(TMP-B300)

Product Details(TMP-B70)

UHSP-OP2060 Ultra High-Speed Sputtering Systems

This film deposition system layers metal/metal-oxide films by sputtering and silicon-oxide films by chemical vapor deposition (CVD) onto three dimensional injection molded plastics including plasma pretreatment in an integrated vacuum chamber.

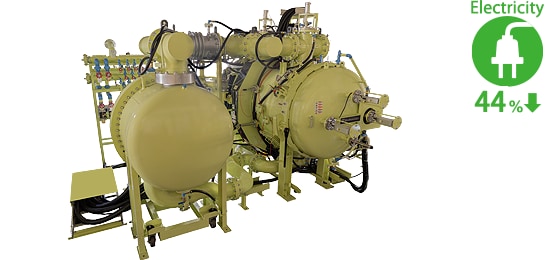

PHSG-U Degreasing Uniform Rapid Cooling Sintering Furnace

This furnace is used to degrease and sinter metal components used in carbide tools, etc. The temperature distribution when cooling the item being processed is about 1/4 that of the previous model, so both rapid cooling and temperature distribution can be achieved. This contributes to improvements in both quality and yield rate.

DSF-60C30 Superheated Steam Degreasing Furnace

This furnace is used for degreasing during the manufacture of ceramic components. It enables the degreasing time to be shortened and electrical power consumption to be reduced. The processes can also be visualized using the monitoring function.