Using Science to Analyze the Aroma and Taste of Craft Beer -GC, GCMS, and LCMS

The ISEKADO has gained a growing reputation in the craft beer industry.

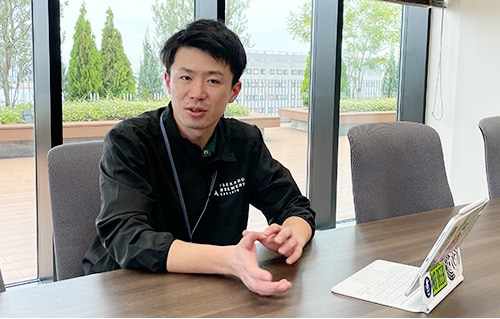

Yusuke Takemori, who oversees beer analysis in the Solutions Center of Excellence, Analytical & Measuring Instruments Division, is collaborating with the brewer working under Narihiro Suzuki, the president of the brewery who believes making beer requires numerical data.

The following is the story of collaboration between the two companies looking to establish the standard for beer analysis.

Forming a Tag Team Generates Win-Win Benefits for Both

The two companies first crossed paths in about 2016 when Takemori sent an email to the Customer Support Center of ISEKADO. Takemori hoped the technically advanced beer company would provide Shimadzu with samples and, in return, Shimadzu would provide them with data that could solve their challenges.

Narihiro Suzuki, CEO & President of ISEKADO

The 21st-generation successor to Nikenjayamochi Kadoya, a confectionery shop operating since 1575 on the main shopping street leading up to the Ise Grand Shrine, President Suzuki started a beer business due to his curiosity about microorganisms. He published a paper about Kadoya’s flagship beer, named “Hime White,” which was brewed using wild yeast (KADOYA1) he obtained from the Yamatohime-no-miya/Kotaijingu Betsugu. Takemori contacted the brewery after he read that paper.

“It was rare to see a scientific paper published by a craft beer manufacturer, so I contacted President Suzuki in the hopes of working together.”

President Suzuki has been interested in living organisms since childhood. In the agriculture department at university, he studied the cultivation of marine organisms and the structural analysis of metabolites. Due to his knowledge about microorganisms and given the importance of fermentation for beer, he felt strongly about the need to use science in beer making, so he replied directly to the email from Takemori.

“Our laboratory has only a few analytical instruments. As a result, in the field of food metabolomics, we are not able to conduct comprehensive quantitative and qualitative analyses of beer to determine which aroma or taste components are involved. However, that sort of analysis would become possible if we worked with Shimadzu. If the resulting data would be useful to Shimadzu, then I thought it would be a win-win situation for both parties, so I said we would be happy to work together.”

Thus, the two companies began a deeper relationship.

Yusuke Takemori, Solutions Center of Excellence, Analytical & Measuring Instruments Division

Numerical Data Provides a Deeper Understanding of the Yeast

Takuma Yamamiya, Manager of Quality Control and a Brewer at ISEKADO

Takuma Yamamiya, the Manager of Quality Control and a brewer in charge of brewing, also feels strongly about the significance of using numerical data in the beer making process.

“Normally, beer recipe adjustments are made based on sensory testing used to predict the characteristics of beer and the elements contained. However, some elements are not apparent until they are numerically quantified by analysis.”

One thing that was visualized by numerical quantification was the amino acid value of a wild yeast obtained in Shimbashi. LCMS and GCMS analysis determined that it had less of a specific amino acid than other yeasts.

“I had been thinking that this yeast had poor fermentation performance and was a little bit difficult to use. However, data showed that the environment where it was originally located was not good and prevented it from achieving its full potential performance,” noted Yamamiya.

They thought its weakness of becoming sweet was due to incomplete fermentation, but improvements in fermentation quantities were achieved by developing a process of supplying more amino acids. That resulted in an IPA-like (India pale ale) flavor, but with a sense of dryness.

Then we brewed that beer using a recipe modified based on those analytical results and offered it in limited batches as a beer created through collaboration between Shimadzu Corporation and ISEKADO.

Kocho Collaboration Beer

Need for Ultra-Trace Component Detection

Yamamiya pointed out that “the project demonstrated the ability to use a wild yeast obtained in Shimbashi to create a beer with specifically targeted characteristics, which represents a significant step.” Just as President Suzuki anticipated, “it was exciting to see what would result from this development-based manufacturing collaboration with an analytical instrument manufacturer.”

Takemori also feels there were significant benefits generated from the collaboration, saying “the ability to analyze substances from various perspectives using GC, GCMS, and LCMS technologies is a key strength of Shimadzu, so I am particularly pleased that data analysis was utilized so successfully. Furthermore, the fact that it clearly showed which data was necessary to produce the beer was a valuable result achieved from working together with ISEKADO. Recently, we started working with Yamamiya again in order to more easily detect ultra-trace quantities of thiol.”

Thiol is a component typically present in ppt (parts per trillion) levels and, though threshold values are very low, thiol is an important component for determining the aroma of beer. Unfortunately, thiol was not detected during analysis in the initial project.

“Though thiol is only present in ppt-level trace quantities, the compound produces an aroma that is detectable in sensory testing. If we can use analysis to determine the function of such tiny invisible components, it will surely broaden the scope of brewing.” (Yamamiya)

The ability to analyze thiol is needed by not only ISEKADO but also other leading beer manufacturers throughout the world.

Yamamiya explained that the beer industry has been striving to find ways to reduce the quantity of hops used to improve sustainability, but that effort involves thiol as well.

“Thiol is one of the key aroma components in hops. I think sustainability could be achieved by developing something that could increase thiol without adding more hops. That something would need to maximize thiol within the limited number of raw materials used.”

Certainly, to better understand the function of thiol, it will be important to have an easier way to analyze thiol.

Making the Craft Beer Industry More Interesting

President Suzuki explained that because consumers expect beer to always have the same familiar flavor (consistent quality control), beer needs to be manufactured scientifically based on data, rather than only relying on the intuition of a brewmaster.

“Promising brewers must have two key characteristics. One is a sense of creativity necessary for generating new things. The other is the ability to scientifically understand and build an approach for finishing the intended beer being created. Since beer is created by fermenting yeast, it takes more than intuition to create it. Unless manufacturing processes are backed by numerical data, the reproducibility of flavors will remain low.”

Beers are assessed based on flavor and aroma, but that typically involves sensory testing by humans. In Japan, many craft beer brewers rely mostly on sensory testing without significant awareness of numerical data.

“The level of the overall craft beer industry needs to be raised in Japan. Within that context, we are looking ahead based on our intention to create world-class beers. We want to use numerical data to create beers that stand out above all others.”

With an aim of creating the industry standard for beer analysis by working together to collect data required by the world, Takemori is feeling more strongly about the collaboration with each new project. If a method for analyzing thiol is announced as well, would it stimulate the craft beer industry?

“Probably some think we should not announce the method, but we intend to announce it publicly and do not mind if others imitate the method. I just want to make the beer world more interesting.” (President Suzuki)

ISEKADO now exports beer to 10 countries around the world and has even started manufacturing beer outside Japan. In the future, if they can develop globally competitive beers based on Shimadzu data analysis, it would certainly make the craft beer industry more interesting. Therefore, the story of collaboration between the two companies will continue.

Note: The Kocho collaboration beer is brewed in limited batches for sale at the ISEKADO. There are no plans to distribute it to retail shops or other outlets.

Note: Information, organizational affiliations, and titles indicated in the article were current at the time of the interview.

Copied

Copied