Advanced Flow Technology Series

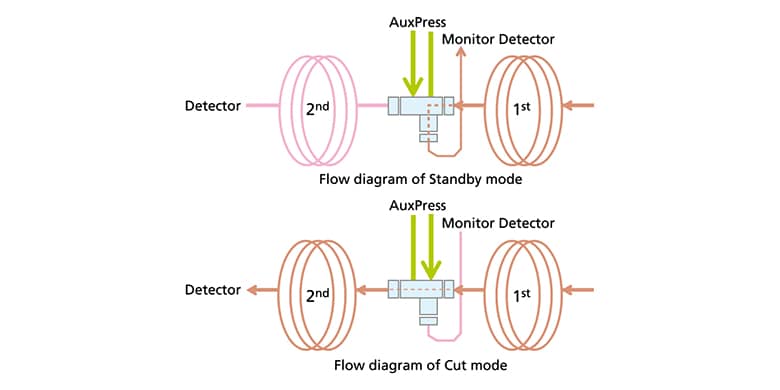

Residual organic solvent in food packaging materials is a problem that receives serious attention because of the implications to food safety and public assurance. While food containers and packaging materials are subject to standards controlled through material testing and testing of leachates from the packaging materials, as specified in Japan’s Food Sanitation Law, the recent heightened concern over safety and assurance has led to the analysis of substances other than those subject to the current control standards in Japan. One example of these is the measurement of acrylonitrile, which is controlled as a carcinogen by the U.S. Food and Drug Administration (FDA) and by regulations in the European Union (EU). Flame ionization detectors (FID) and flame thermionic detectors (FTD) are used for GC measurement of acrylonitrile, but this analysis is often time consuming due to the presence of high-boiling substances in the liquid extracted from resinous materials, which are slow to be driven from the column. In addition, when an FTD is used as the detector, reduced stability and deterioration of the detector are concerns, depending on the solvent that is used. A backflush GC system is one in which the carrier gas flow is reversed after the elution of the analytes from the column, so that the high-boiling substances are expelled from the injector split vent. This elimination of the backflushed high-boiling substances not only serves to protect the column and prevent contamination of the detector, it can greatly shorten the analysis time. This Application News introduces a fast analysis of acrylonitrile based on the use of the backflush GC system.

January 29, 2010 GMT

Some products may be updated to newer models