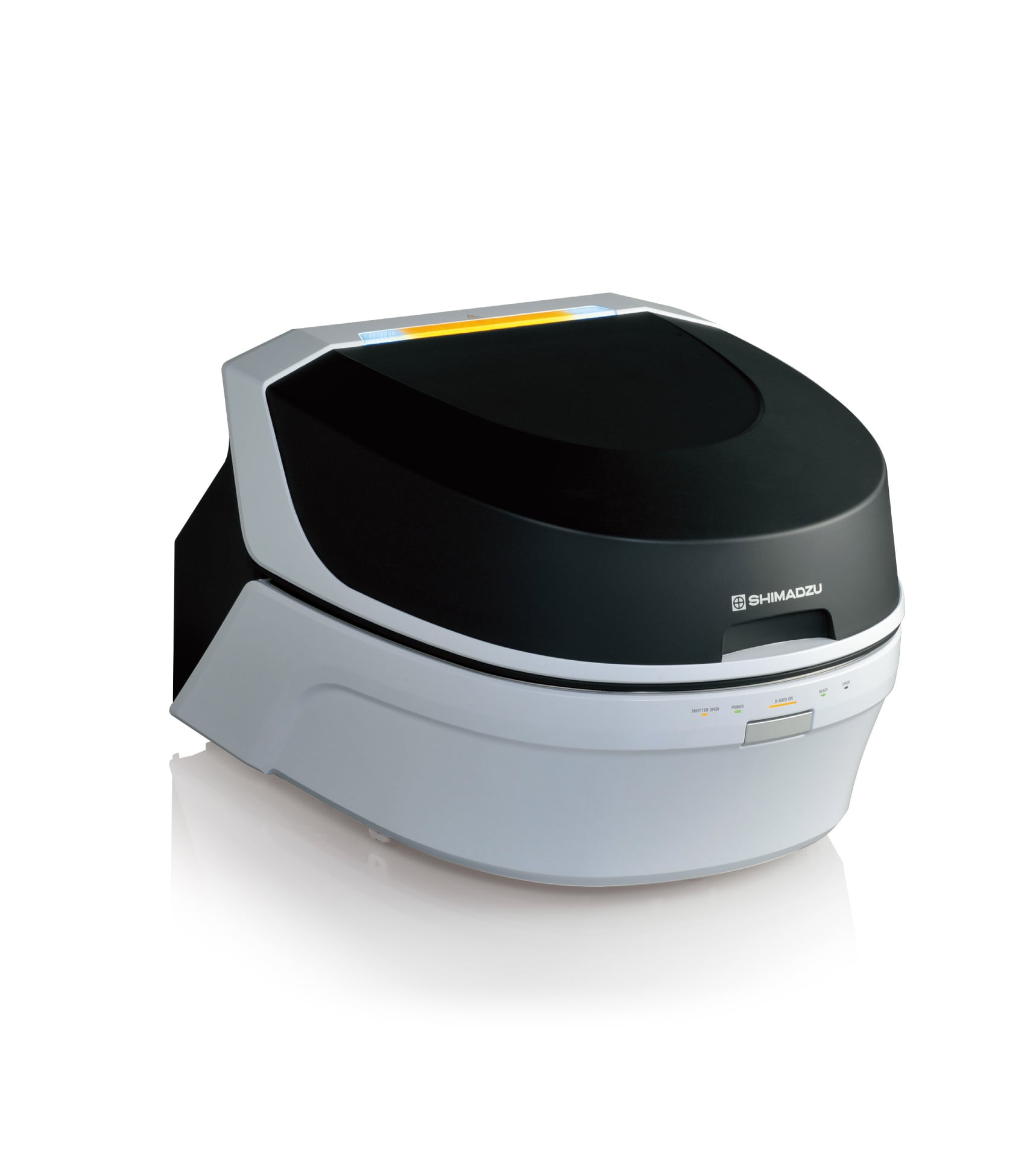

EDX-8100

- Slag can be easily analyzed by simply setting it into a sample cell. - Additional calculations based on the quantitated values, such as basicity, can also be included in reports. - By press molding samples, fluorine (F) can also be analyzed (EDX-8100).

Slag is a byproduct of the metal smelting process that contains a mixture of reduced metals, separated minerals, and residual reducing agents remaining from the smelting process. There is also what is called molten slag, which is made by melting and solidifying waste such as incineration ash and sewage sludge. The principal components in slag include silica (SiO2), and metal oxides from the raw materials, such as alumina (Al2O3), iron oxides (Fe2O3, FeO), and calcium oxide (CaO). Slag can also contain trace quantities of heavy metals and fluorine (F). Slag components are analyzed using an X- ray fluorescence spectrometer, which is important for reusing the slag or managing the conditions of slag formation. Conventionally, wavelength dispersive X-ray fluorescence (WDXRF) spectrometer was commonly used to analyze slag, but now energy dispersive X- ray fluorescence (EDXRF) spectrometer is increasingly used due to easier operability, simpler sample handling, and higher quantitative accuracy. This article describes an example of using EDXRF for qualitative- quantitative analysis of blast furnace slag (EDX-7200) and for quantitative analysis of fluorine (F) in electric furnace slag (EDX- 8100).

October 26, 2022 GMT

Some products may be updated to newer models