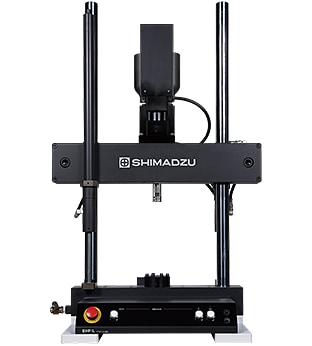

EHF-L Series

- It is possible to test in accordance with JIS K 7118 “General rules for testing fatigue of rigid plastics” by using the dynamic and fatigue testing system Servopulser, EHF-L Series. - High-accuracy dynamic control can be achieved with Servo Controller 4830. - The surface temperature of the test specimen can be measured in real time, and the collected data can be incorporated into the control system.

Plastic materials are widely used in daily necessities such as PET bottles due to their light weight, low cost, superior moldability, and colorability. In recent years, in addition to general-purpose plastics such as polyvinyl chloride (PVC) and polyethylene (PE), engineering plastics with improved heat resistance and mechanical strength such as polycarbonate (PC) and polyamide (PA) have attracted attention. These materials are used as structural materials and mechanical components in automobiles, aircraft, and piping, and are increasingly used in applications that require performance in particularly harsh environments. In the process leading to the failure of a material, even a small load such as vibration that does not break a material with a single load can cause failure due to repeated action. This phenomenon is called “fatigue.” Because plastic materials used as structural materials are expected to be subjected to repeated loads over a long period of time, evaluation of fatigue characteristics is essential for product safety. This article introduces an example of fatigue testing of plastics in accordance with JIS K 7118.

September 23, 2025 GMT

Some products may be updated to newer models