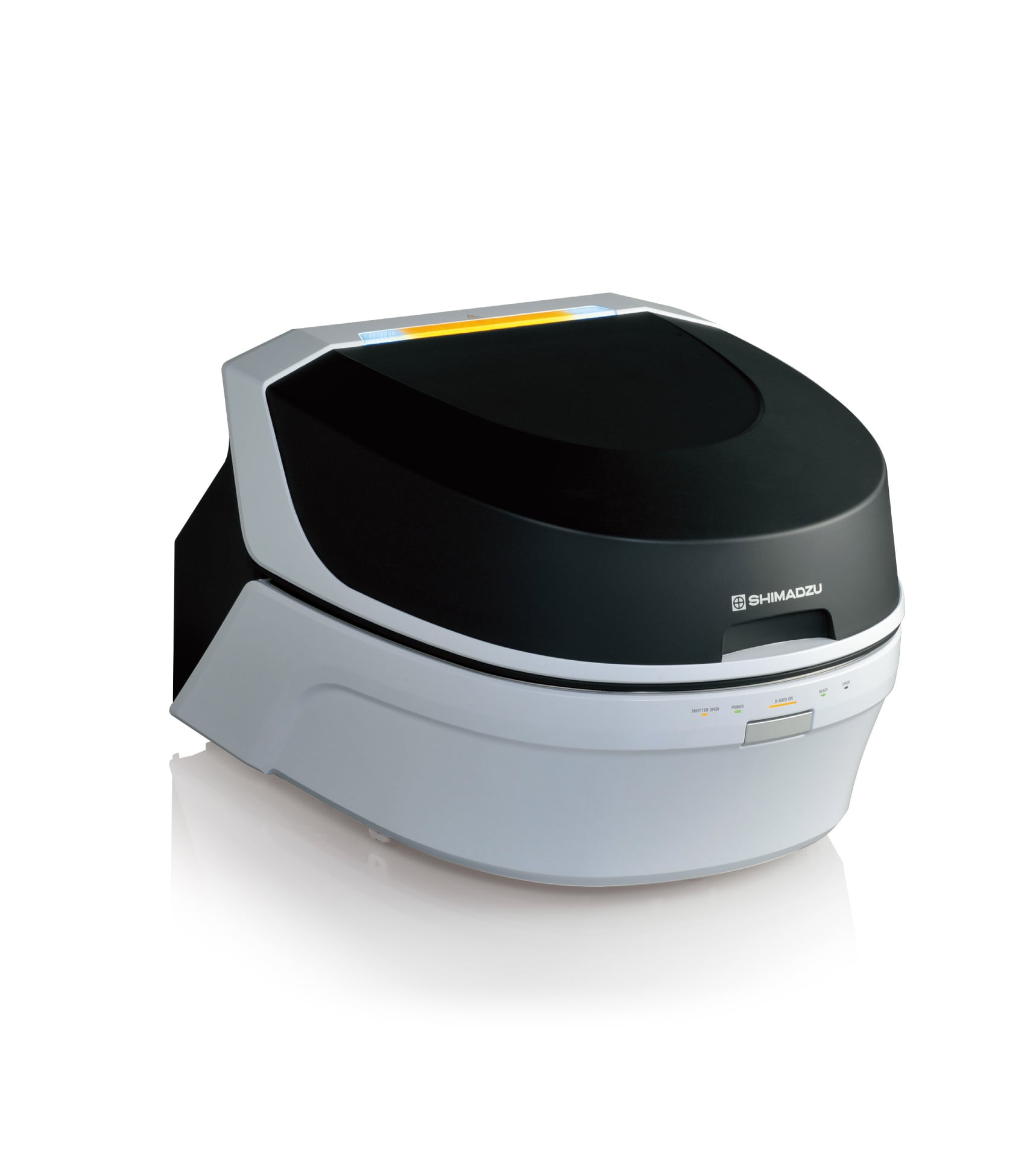

EDX-8100

- EDXRF enables analysis of Na and K, which cause fluidization problems (agglomeration) in circulating fluidized bed boilers in biomass power generation. - Simple qualitative/quantitative analysis of elements is possible with minimal sample preparation. - Comparative analysis of heterogeneous samples in the as-received condition and in the homogenized condition after crushing is possible.

In biomass power generation, electricity is generated by using bioresources (biomass) derived from animal and plant sources as a carbon neutral fuel. Biomass power is expected to contribute to reducing total CO2 emissions, and in recent years, the number of woody biomass power plants using wood chips, pellets, and palm kernel shells (PKS) has increased. Circulating fluidized bed (CFB) boilers used in woody biomass power generation generate power by circulating and burning biomass fuel together with silica sand, which is as a fluidized bed medium. However, alkali metal elements (Na, K) contained in the fuel adhere to the surface of the silica sand and combustion ash, causing the particles to stick together and form agglomerates (lumps, coarse particles), which are considered to cause boiler damage and fluidization problems (agglomeration) in the fluidized bed. In this article, a Qual-Quant analysis of PKS combustion ash and its coarse particles was conducted using an EDX-8100 energy dispersive X-ray fluorescence spectrometer (EDXRF). Since adhesion of alkali metal elements was detected on the surface of agglomerated lumps, which are considered to cause the problem of agglomeration, analysis of combustion ash by EDXRF can contribute to operational management of combustion furnaces by monitoring the conditions in the combustion furnace.

October 21, 2025 GMT

Some products may be updated to newer models