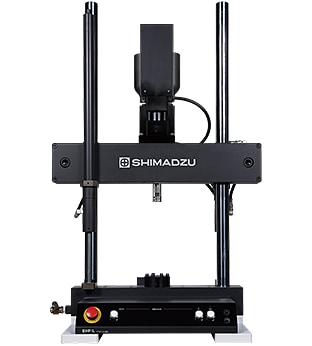

EHF-L Series

- Shear fatigue testing of SiC chips mounted by silver sintering is possible by using a SiC chip fixture with a fine-adjustment stage. - High-accuracy dynamic control can be achieved by using the Servo Controller 4830. - X-ray CT allows nondestructive observation of the internal condition of SiC chips and Ag sintered bonds.

Silver (Ag) sinter joining is a technique in which particles are bonded together by heating/compression of a paste containing silver particles. In recent years, attention has focused on EVs (electric vehicles) as a key technology for realizing a decarbonized society, and wide bandgap power semiconductors such as SiC, which are expected to reduce energy loss and provide excellent heat conduction/heat resistance, have become indispensable for improving EV performance. In particular, with the use of large current/high density power semiconductors, performance under high temperature environments is now required. To achieve this, Ag sinter joining has attracted interest, as Ag sintered bonds can maintain good mechanical properties under higher temperature environments than conventional solder bonds. In this article, a shear fatigue test of the bond between a SiC chip and a copper substrate formed by silver sinter joining was conducted using a Servopulser dynamic and fatigue testing system, and the fracture mode of the SiC chip after an endurance test was observed using X-ray CT.

December 9, 2025 GMT

Some products may be updated to newer models