Birth of the First HPV

High-Speed Video Camera HyperVision HPV-1

0. Introduction

How does a golf ball deform at the moment of impact with a driver?

How is gasoline discharged from the injector nozzle of an engine?

How do cracks in a piece of glass propagate at the moment of breakage?

High-speed video cameras are essential for visualizing ultrafast, momentary phenomena that occur faster than the blink of an eye.

The HyperVision HPV-1, launched by Shimadzu in 2005, has enabled the previously unheralded visualization of ultrafast phenomena in fields where high-speed imaging is required, such as product development, causal investigation of defects, research in science, engineering and medicine, and sports science.

However, various difficulties and challenges had to be overcome to realize this state-of-the-art technology combining a maximum recording speed of 1 Mfps with high-resolution image capture.

1. CCD Image Sensor with Memory Built into the Sensor Chip

(affiliation at time of product development)

In 1999, Yasushi Kondo of Shimadzu Corporation’s (then) Technology Research Laboratory received a request to participate in a joint research project.

Professor Etoh of the (then) Department of Civil Engineering in Kindai University’s Faculty of Engineering approached him with what seemed to be an absurd proposal—to develop an ultra high-speed video camera with memory built into the image sensor chip.

Kondo paid an urgent visit to Professor Etoh. After listening to the details of his proposal, Kondo realized that it was a groundbreaking idea to use the CCD structure to create memory adjacent to the pixels, and to integrate this memory into the CCD image sensor. However, he had lingering doubts about the feasibility of the concept.

However, upon further investigation, Kondo discovered that the basic concept for this high-speed CCD had already been published in a paper by the world-renowned Professor Walter Kosonocky. He also learned that Professor Etoh has previously collaborated with a high-speed video camera manufacturer in Japan to develop the world’s first high-speed video camera with a solid-state image sensor.

Against this backdrop, the pair held out tenuous hopes of realizing a CCD with memory built into a sensor chip, and research was commenced.

2. Joint Development with CCD Manufacturer

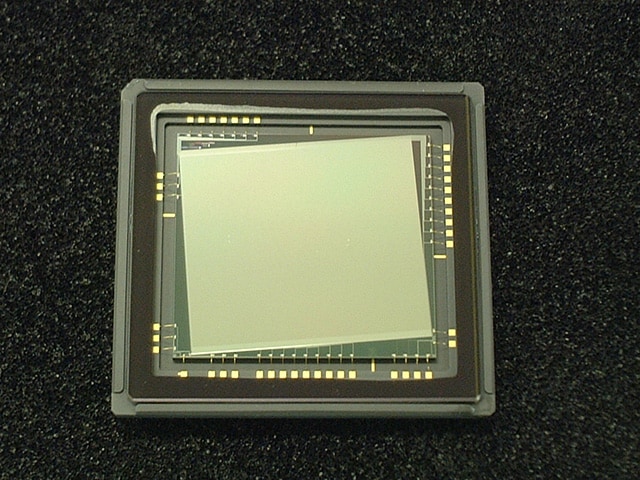

(The chip is packaged diagonally by design because the pixels are arranged diagonally)

The key to this project laid in how to feasibly manufacture the high-speed CCDs conceived by Professor Etoh.

CCDs are expensive to manufacture and require many sensors to be fabricated at one time. As a result, the developers could not find a domestic manufacturer that could meet their requirements.

However, thanks to the efforts of Professor Etoh, a major electronics manufacturer based in the Netherlands (referred to here under the anonym of “Company P”) agreed to jointly develop the product.

Professor Etoh and then researcher Soya from our company traveled to Germany and began designing the high-speed CCD with the help of engineers from Company P.

At the time, Company P was at the forefront of CCD technology and employed many globally renowned researchers.

Their interest and willingness to collaborate on this research enabled us to manufacture the high-speed CCDs using Company P’s cutting-edge technology.

The high-speed CCD was finally completed and then researcher Takubo at our company, who was eagerly awaiting its arrival, began testing the CCD’s operation.

The testing was successful and we finally succeeded in realizing high-speed recording of 1 Mfps.

3. Practical Use Testing

-

The technology that we strived to develop would have been meaningless if it was not adopted by our customers.

We therefore built prototype cameras using a small batch of prototype high-speed CCD chips and took them to the laboratories of potential users to demonstrate its recording capabilities to gauge the potential market.

The product was well-received and many universities and companies expressed an interest in purchasing it.One particularly memorable response came from the technical manager of a printer manufacturer who happened to see the prototype at a tradeshow and commented: “This camera will allow us to see inkjet droplets that were previously invisible”, and then tentatively ordered several units of the finished product that he viewed as essential for the future development of high-definition printers.

The project seemed to be progressing smoothly.

-

Ink Discharge from an Inkjet Printer

Recording Using a Test Version of the CCD

4. Launch of the HPV-1

After earning considerable praise for the prototype from users, Shimadzu placed an order with Company P to manufacture chips for the product, at which point events took a dramatic turn.

Company P had just sold its CCD division and the manufacturing of high-speed CCDs was transferred to another plant.

CCD manufacturing is extremely intricate, so it is difficult to recreate the manufacturing conditions if the plant changes.

Consequently, the high-speed CCDs fabricated at the new plant did not function as intended, resulting in virtually zero yield.

Shimadzu worked with process engineers at the new plant to make numerous improvements and prototypes.

Meanwhile, the printer manufacturer was patiently awaiting delivery, and our senior management encouraged the product development team not to give up and continue development.

Ultimately, three years were needed to realize a stable and operational iteration of the high-speed CCD.

Then, after overcoming these hardships, the HyperVision HPV-1 was launched on March 23, 2005, as the world’s first 1 Mfps high-speed video camera.

5. Marketing

President, Hadland Imaging

For some time after its launch, the HPV-1 sold well for research applications such as inkjet printers and space development.

However, the sales volume in Japan was sluggish due to the limited number of users requiring ultra high-speed recording.

Overcoming this hurdle would require shifting our focus from domestic to overseas sales.

However, the HPV-1 was subject to export restrictions so overseas sales were limited to the U.S. and Europe, making it crucial to market the product effectively in these regions.

Coincidentally, one of our U.S. distributors had in its employ a sales representative who was achieving phenomenal sales results. That sales representative was Todd Rumbaugh.

Due to his extensive knowledge of ultra high-speed video cameras and the users engaged in cutting-edge research, Todd was selected as our primary sales contact in the U.S.

He also provided significant insights to our product development team on the types of users who perform ultra high-speed recording.

6. The Challenge to Develop a CMOS Image Sensor

As sales of the HPV-1 increased, users began asking for even faster high-speed cameras.

However, it had become evident that CCDs have various drawbacks, such as an increased risk of failure due to excessive heat generated by increases in high-speed operation and electrical instability if the incident light is too intense.

To solve these problems, the product development team decided to change the sensor from a CCD to a CMOS image sensor (CIS).

However, CCDs and CISs employ different principles and structures, making it necessary to recreate the design and manufacturing processes entirely from scratch.

Thus, with the future of Shimadzu’s high-speed video camera at stake, we visited Professor Sugawa of Tohoku University, a leading expert in CIS research, to seek his participation in joint research on a high-speed CIS capable of operating at a recording speed of 10 Mfps.