Fuel Cells | Water Melting Process in Solid Polymer Membranes (DSC)

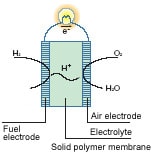

Solid polymer membrane fuel cells are used for various domestic, automotive, and mobile applications, due to their low operating temperature and high-generation capacity per unit volume. The smallest unit in a solid polymer membrane fuel cell is the cell, which comprises a fuel electrode (cathode), solid polymer membrane, and air electrode (anode). A large number of these cells form a stack.

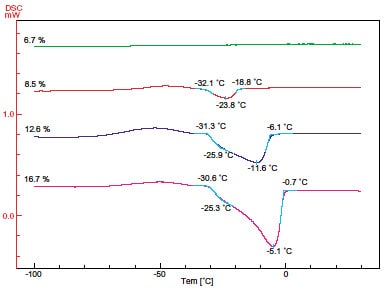

The water melting process in solid polymer membranes with different water contents was measured by a DSC-60 Differential Scanning Calorimeter.

Fig. 1 shows the measurement results for the water melting process in solid polymer membranes containing different percentages of water.

No water melt peak was observed at the 6.7% water content. The -23.8 °C peak for the 8.5% water content polymer membrane can probably be attributed to the melting of water clusters in the membrane. At water contents of 12.6% and above, a two-stage peak is observed, which can be attributed to the melting of bound water clusters and free water. In addition, it is evident that the high-temperature peak associated with the free water increases as the water content increases.

Photones generated at the fuel electrode pass through the solid polymer membrane and move to the air electrode.

DSC-60 Differential Scanning Calorimeter

A newly developed high-sensitivity detector doubles the previous peak heights. The 1 µW (RMS) max. noise level permits cooling measurements without the need for options. Automatic detector cleaning.