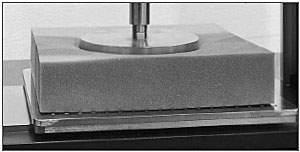

Compression Test Jig for Foam Specimens

Features:

- Applicable to compression testing rubber foam and urethane foam specimens

- Compliant with ASTM D3574 and JIS K6384 standards

- Perforated support plate enables air to escape from the foam during testing

- For testing below 1 kN (220 lbf)

Relevant Materials:

Rubber Foam, Urethane Foam

Relevant Specimens:

Cuboids

Relevant Standards:

ASTM D3574, JIS K6384

This compression test jig is specifically designed to test rubber foam and urethane foam specimens that are molded, cored from a larger sheet, or shaped, for example, having a dimpled pattern.

The compression test jig for foam specimens consists of a 200 mm (7.9 in) diameter upper compression plate and a larger 400 mm (15.7 in) by 400 mm lower support plate. The lower plate contains holes 6.5 mm (0.26 in) in diameter, spaced 20 mm (0.79 in) apart. The perforations are designed to allow air to escape from the foam during testing.

Common tests applicable to rubber foam and urethane foam include compression to a specified deflection or force, where the resulting force or deflection, respectively, are measured, and maintenance of a constant deflection with measurement of recovery.

Compression test kits for foam specimens are available in certain regions. In addition to the compression test jig, these kits include a compression and bending loading jig. Please contact your local Shimadzu representative for details.

This compression test jig for foam specimens cannot be installed on universal testers with safety covers attached.

News / Events

-

AUTOGRAGH AGS-X2 Series has been released

The Shimadzu AUTOGRAPH AGS-X2 series provides superior performance and practical testing solutions for a wide array of applications. Offering high-level control and intuitive operation, the AGS-X2 series sets a new standard for strength evaluations while providing the utmost in safety considerations in a modern, stylish design.

-

AUTOGRAGH AGS-V Series has been released

Shimadzu Corporation released the Autograph AGS-V Series precision universal testing machine. In this series, the range over which the force measurement accuracy is guaranteed has been increased by a factor of two compared with existing machines. As a result of this new function, the work required to change force measurement sensors and accessories required for measurement can be reduced.

-

High-Speed Video Camera HyperVision HPV-X3 has been released

Recording speed of 20 million frames/second, the highest in its class provides larger, clearer, high-sensitivity recording. HPV-X3 is equipped with a synchronized recording function and high-level analytical capabilities that accommodate a variety of software programs.

-

New Video: AUTOGRAPH AGX-V2 Voice Operation Device XV-Talk

We will introduce how XV-Talk, the world's first voice control device installed in Shimadzu's latest tensile tester AGX-V2, can be used in various scenarios.

-

New Video: AUTOGRAPH AGX-V2 Operation Control Panel Stand-alone test feature

We will introduce a new feature of Shimadzu's latest tensile tester, AGX-V2, a stand-alone testing function using a large color LCD touch panel.

-

New Autograph AGX-V2 Series Precision Universal Testing Machines

The World’s First Testing Machines Equipped with a Voice Operation Device